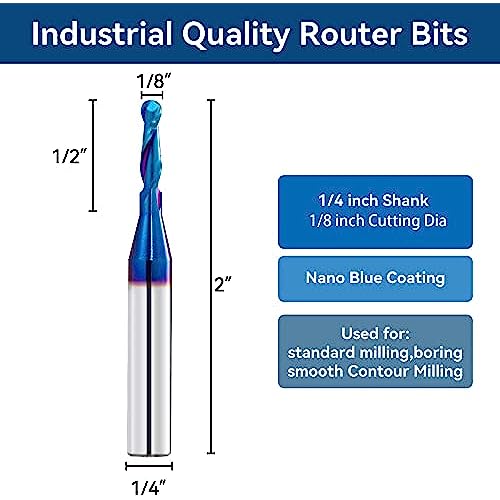

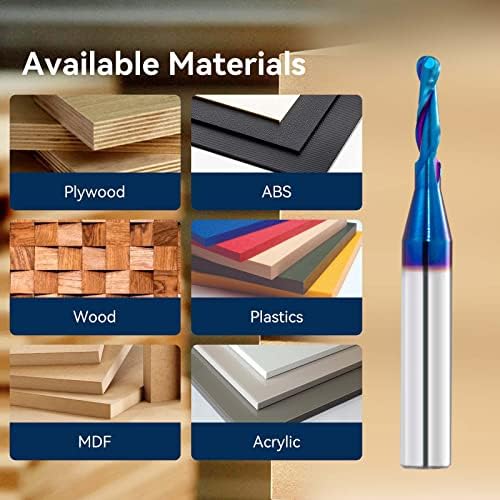

CNC Router bits Carbide Ball Nose End Mill with Nano Blue Coating 1/4inch Shank 1/8inch Cutting Dia for Side Milling End Milling, Finish Machining (1/8x1/4x2)

-

Chris

> 24 hourThis CNC router bit by Yokishun is a ball nose end mill bit that is made incredibly well and it cuts perfectly! I use it more for end milling rather than side milling and finish machining, but I have no doubt it will work for any of those applications. I highly, highly recommend it!

-

Larry

> 24 hourLooks really rugged I think it will las a while

-

Woodworx

> 24 hourVery sharp I use it in my 3D engraving. It has held its edge very well after many hours of use. I get a clean burr free cut.

-

Timothy Watts

> 24 hourSo I ordered this bit to use as I practice/learn how to become more proficient and with less mistakes in my carvings. It takes a bit of getting used to, because of the effectiveness of the cutting head. This leaves a really smooth surface as it clears out the wood you are working on removing . I dont have anything to show just yet (mostly because I do not want to embarrass myself ), but this is the first “Ball Nose” bit I have ever used. I am hoping I get to a point where I am able to create anything I want to with this bit, and make it look nice enough to keep it out of the scrap/burn pile. I’ll update with info and/or pictures as I discover issues, tips, and pictures.

-

Tory L Kaufman

> 24 hourI carving

-

Duane

> 24 hourSmooth cut and seems to work well. I cant attest to the longevity of this bit yet, but the initial cuts look great.

-

Richard Shepherd

> 24 hourto us on the bit on an CNC you have to have the specification for the bit. required is speed cut rate and other. the YOKISHUM has no web link and can not find the name in the web.

-

David M Lee

> 24 hourDoes a great job of putting a very fine finish on my carving projects.

-

Kris

> 24 hourIm fairly new to using ballnose bits. Ive primarily used V bits and flat endmills for the past couple of years on my CNC machine. However, I recently started to experiment with ballnose bits and cutting from some basic 3D files. As you can see in the photo, I made a mancala board and used the ballnose to shape out the bowl shapes. While you do need a decent bit, 90% of the end result is how you set up your file and toolpaths in the software. That being said, I felt like I got great results with this bit. The cut was sharp and it performed as I expected. I havent noticed much difference between bits with the nano coating and bits without, but I do hope it increases longevity over time.

-

Michael F Fiumano

> 24 hourlooks like a great bit, havent tried it yet, but i expect it will do the job well.