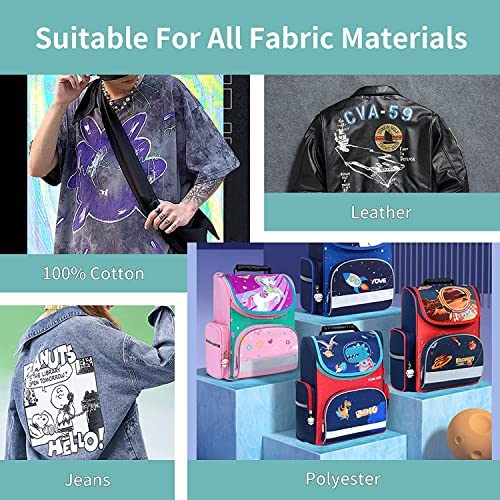

Jecqbor DTF Powder White Digital Transfer Hot Melt Adhesive, 400g/14oz DTF Pretreat Powder for DTF Printer Direct Print on All Fabric Include Jeans Cotton T Shirt Textile etc

-

Pheenyx Monroe

19-04-2025Works as intended

-

Kristopher G.

Greater than one weekPros: This heat transfer paper is pretty inexpensive and works very well. The pictures printed on them are very clear and crisp. They transfer easily with heat and once transferred the pictures look very good. They work much better than expected for the price. Overall: This heat transfer paper works great for a great price. I highly recommend them.

-

Missy

> 3 dayGood quality nice prints

-

Nina Flaa

> 3 dayThis DTF film is extremely difficult compared to others I’ve bought from Amazon, if you are in a pinch and don’t have time to replace shirts do not use this product.

-

Koihana Hebel

> 3 dayWe really like these inks. They give you 2 bottles of white, which is nice as you burn through a lot of white! So far, we have tested this ink in our L800 and 1390 based printers and it works just fine. The coverage is good and is color accurate. It also binds well with the dtf powders.

-

Irace4fun

> 3 dayNice bright colors. Smooth printing. I would recommend these.

-

Major West

> 3 dayMy wife buys this regularly for her design and print hobby. She recently began doing t-shirts and, after some trial and error, is producing some pretty decent images. If youre just starting out, educate yourself on the craft first. Success depends on technique rather than brand of DTF powder. My wife has found very little difference among the various brands shes purchased. This powder is a good value.

-

Christina

> 3 dayI have been asked to review this product with my honest and unbiased opinion. It works exaxtly.how its supposed to. Great color transfer that holds up.

-

DHWAustin

> 3 dayAfter reading other reviews I wanted to try the diy hack of using this with powder and my inkjet printer. The printer had trouble loading each page. It was as if it was too slick or something. I have used normal transfer transparency paper many times. I’m not sure why but I had trouble several times. After hand feeding the paper in, the design was bright and colorful. Although it looked good, Unfortunately my image peeled right off after 5 hours of wear. I was hoping this hack would work for me but it did not. So if you’re thinking of trying this hack I can’t recommend it. To use as the product was intended it might work fine but you might have trouble getting your printer to pick it up for loading .

-

debi berryhill

> 3 dayGreat size bottles and easy to fill, the colors print out beautiful and vibrant and press well. This is now among my top two go to inks from now on :)