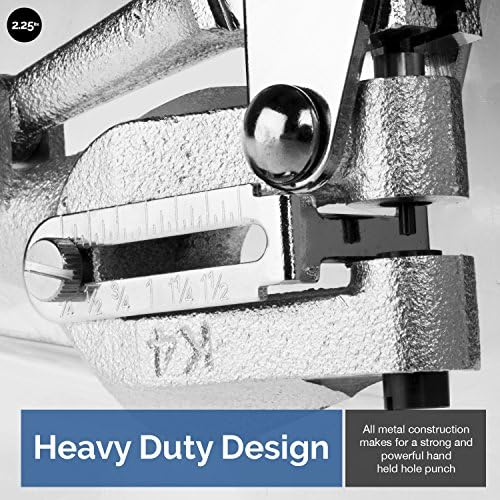

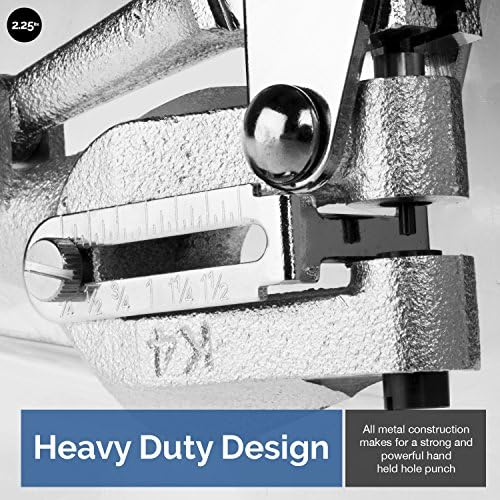

NEIKO 02612A Hand Held Power Punch and Sheet Metal Hole Punch Kit, Various Size Hole Punch in 3/32 to 9/32, Heavy Duty Hole Punch for Metal, Leather, Compound Leverage Punch

-

MarDav

> 3 dayIt punches perfect holes in the aluminum material that Im using. The only improvement that I can see is to make the handles ratcheting. Other than that it is a good tool to have around.

-

Joe Mooney

> 3 dayThis is my first hand held punch, so I cant compare this to other products of this type. That said, this is a hefty well built device that is comfortable to use and makes clean holes in a variety of materials. I tested it on thin sheet metal, leather, thin plastic, and thick wads of paper. In every case it worked very well. Switching between hole sizes is a bit fiddly, but nothing too difficult once its been done a few time. Definitely one of the better built hand tools Ive encountered in many years of DIY work. Now I just need to put it to some practical use! PS - Bought this from the 3rd party seller: Go Industrial Tools.

-

Moon-tai Yeung

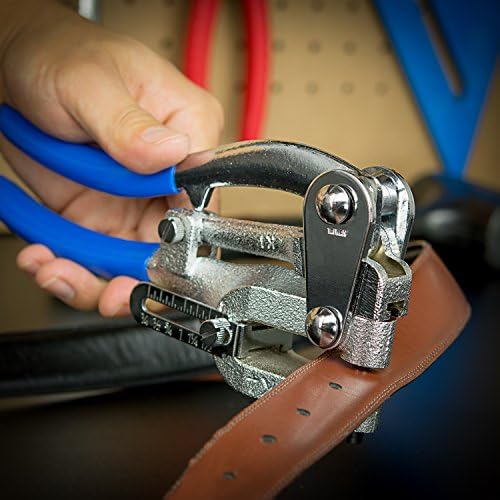

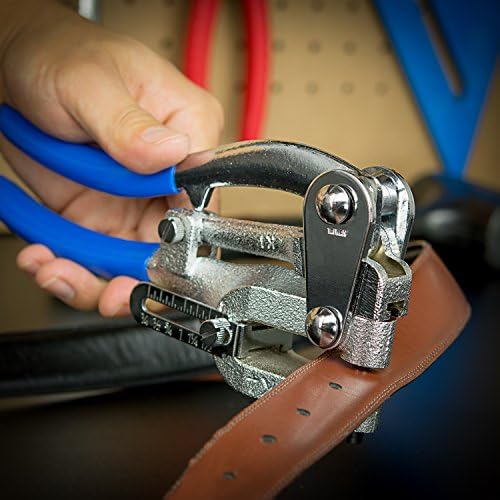

> 3 dayThis is what one would call a heavy duty tool. The whole thing is solid casted metal machined to good precision. Heart of the tool are the punch and die pairs. There are 7 of them, from a little less than 1/8 to a little over 1/4. All pairs fit well together out of the box. The larger sizes tend to fit looser though. I tried all of them on an old computer case and all holes came out clean. Hole sizes were also accurate. In terms of usability, I recently used it in a project to punch around forty 1/4 holes on 26g flashings. This is what I found: 1) The throat depth (1-3/4) is good enough for most uses. But the jaw opening is pretty small, 1/4 according to spec. Since the jaw is fixed, you have to retract the punch side all the way and unscrew the die side way down to get that. My flashings has a 1/8 lip and getting it in and out of the jaw was awkward. 2) Since the jaw is fixed and narrow, it is very difficult to center your hole by sight. One option is to use a center punch to mark the hole first and then use the pointed tip of the tools punch to center on the mark by feel. What I ended up doing was to turn the tool upside down to see my pencil mark through the die. Then I applied small pressure until I see the dimple caused by the punchs pointed tip at my mark before punching through. 3) To make good holes, the die must protrude a little above the bottom of the jaw. However, the die only fits (screw-in) loosely, so you must check/adjust it for every hole. 4) On the other hand, you should not protrude the die into the jaw to much; otherwise, the handles will spread very far apart and you will need two hands to operate the tool. I made a mistake at the beginning and made some holes one size (1/32) too small. I switched to the right size and was able to make clean holes over the smaller ones. Overall, I was impressed. By the way, the tool is made in Taiwan, which I found to have better QA than China. Even so, I think the 16g capacity is overstated.

-

Anissa Witting I

> 3 dayI am an armourer who makes battle ready plate armour from heavy 16 gauge steel, so I do a lot of drilling and have destroyed many drillbits. This is the best hole punch on the market, turns 20 minutes jobs into 30 seconds. Holes punched are clean, no more clean up after drilling! The punch has a real weight to it and feels sturdy, not cheap. The tool was in pristine condition and well oiled. Punching through 16 gauge is impossible by hand, but if you clamp your workpiece down in a vice and and use a solid bench or anvil as support, it punches through with no problem. Use a pipe on the handle for more leverage, works much easier. Punching multiple holes together to make a slot works flawlessly and it can even deburr. The punch is about 2 inches deep, which means I will still use a drill for anything deeper than that, but for 90% of my needs, the punch will be used. Saves me a lot of time and really cuts down on noise compared to a drill. Once you get a bit of practice this punch is so much faster and more efficient than a drill. Im kicking myself for not buying one sooner.

-

Kindle Customer

> 3 daySee picture. Worked well on the sheet metal I bought for making some auto tailight holders. The metal I used it on was think sheet metal - 0.018 Inch thick. I effectively punched out holes for the various size bits and did not leave any rough edges. Its design means it just punches out the hole. It was a little tricky to use the first time, a fair amount of pressure is needed and then it goes pop. Once I got used to that it was fine. Changing the bits is a little tricky with a couple of adjuster screw.s Nothing that bothered me once I got used to it. Be sure to use the matching cup for the bit to ensure that the right size hold is punched out.

-

Jennifer Bridges

> 3 dayBought three of these as gifts. All recipients like them and say they work well on leather.

-

Srinivasa

> 3 dayThis punch is built like a tank. It weighs more than 2 pounds -- but it is designed so well that you can hold it comfortably and use it easily. It comes with the smallest punch already installed -- so, dont freak out when you open the box and see empty slot where the 3/32 punch and die are expected to be. You will need to see online videos to figure out how to change the punch bits. When you press down on your belt or handicraft, it is almost as though some hydraulic powered press kicks in -- and the bit will punch through the toughest belt *cleanly* and with a snap. It was a breeze using it, and I am very happy I bought it.

-

happytilton®

> 3 dayI bought my Neiko Hand Held Power Punch to punch holes in dog collars that have the plastic covered nylon web. It does an excellent job, but does leave a little fur from the webbing. It is constructed from cast iron (heavily built like a tank) and requires very minimal effort to punch through the webbed collars. It comes as pictured in the plastic case with molded slots for everything. The punches & dies are very close tolerance, but those fine nylon hairs are hard for any tool to cut cleanly. It punches 95% of the webbing through with the two sides of the plastic coating. The jaws are only open slightly wider than 1/4, which necessitates good light and turning the tool so you can see down through the hole in the die to line up on your marks. The depth gauge is adjustable to ~2 and is marked, but no marks on the tool to line them up with...No big deal because I would measure it first anyway. As others have noted, the supplied screwdriver tool is stamped from very soft steel and will twist out of shape on the first use...Just figure on using a short flat screwdriver from the get go. It is stamped as made in Taiwan, but workmanship is very good...At least its not made in China! I tested it on thin gauge steel and a 1 plastic strip (.020 thick) that I use as a template to mark the hole locations on the collars...Worked well on both. Bottom line here: An excellent heavy duty tool that is a steal @ $27.79 with 2 day shipping on the Prime! It is from eToolscity (Fulfilled by Amazon) and was surprised to receive it the next day!

-

Tosin

> 3 dayI was wondering if this could work, I just couldnt wait to test it on my copper bars. Without efforts the punch was amazing, what a wonder, amazing item bought on Amazon.

-

M. Kasdin

> 3 dayPrice was very good. The casting for the tool and quality build is excellent, what you would expect form a Taiwanese company. I was able to punch 16 gauge .070 metal galv. sheet metal. I did have to use the edge of a table and bear into the tool to gradually punch through the clip. it took a lot of grunt power, but the tool didnt flinch it powered through. The stop that sets the depth is not particularly good, but it will work. The case is good and the female die on the bottom is a bit loose. I think you could wrap around a little teflon tape around the bottom die to make it more secure. I was tossed between the four star and five star. But with the price so affordable and shipping fast it gets 5 star. I havent used the tool much but i am fairly impressed and i think with casual use it will last a long time. If you were a professional and wanted to use it everyday, for hours on sheet metal, you might opt for the Roper Whitney, but is is really hard to fault this tool which is nearly an exact copy of the RW 5 Jr for less than half price. The dies seem to be quite good. I have used the 1/4 and 1/8 die set. The smaller size punches cut through the metal like butter. I will get back to the review in a few weeks after i have used the tool for more than a few times. Only had the tool for around 10 days. this tool is nearly an exct copy of the RW, their 50 year old patent has expired, so the negative reviews are probably from Roper Whitney?