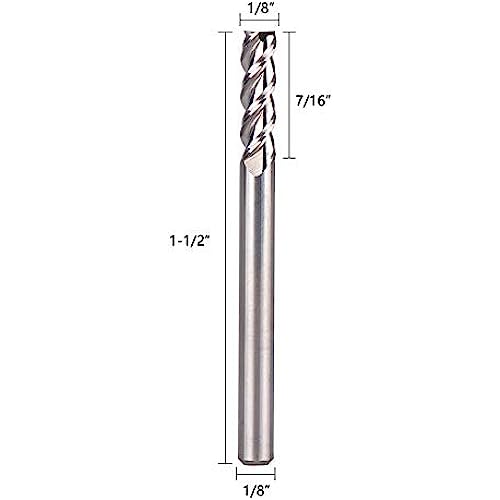

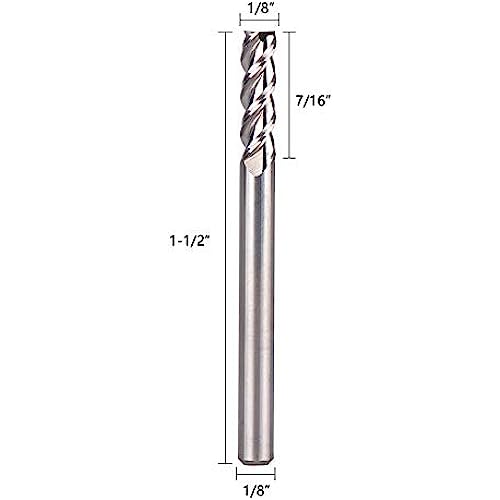

SpeTool 1/8 End Mills for Aluminum 3 Flutes CNC Spiral Router Bits for Aluminum Cut Non-Ferrous Metal Upcut 1.5 inches Long 5 Pieces

-

Phil

> 3 dayWell made end mills. Able to fine cut names in heart boxes for Christmas gifts.

-

William Napier

> 3 dayI have been cutting 1/9”aluminum plate for a couple days . Tried these bits as it said aluminum so cuts worse than my other bits and running slower broke 2 bits in 10 min didn’t make it through first pass so I’m done these won’t work for me .

-

Dylan

> 3 dayI’ve been hogging out aluminum on my Sainsmart Genmitsu 3020 for months now and I’ve never broken a single endmill. Solid product.

-

Mary

> 3 dayThese bits are absolute junk. They break at the slightest side load when cutting aluminum. Might be good for foam or soft wood, but NOT cutting hardwood or aluminum. SAVE YOU MONEY!

-

Sandy

> 3 dayIt works great on acrylics. But not aluminum. It broken after I used it on aluminum.

-

Josh Yost Sr.

> 3 dayYes Great product worth the money and has done its job well.

-

ElRubio

> 3 dayBest for the money can’t lose on this i will buy again

-

Richard Stricklen

> 3 dayCut 1/8 6061 sheet with them. Cut nice and have lasted well.

-

Hyudryu

> 3 dayThese bits work great on desktop CNC machines for milling aluminum. For the price, you get 5 bits which is nice. The only downside about these bits is that they are uncoated, so they do wear out relatively quick when compared to a coated bit. But other than that, I have no other complaints. I was able to get very smooth finishes from facing, after a finishing pаss of 0.002”.

-

Katherine D.

15-04-2025Worked well, as described. Weve cut 4 gearbox plates and a bunch of other 1/4in alumimum with a small router and these bits.