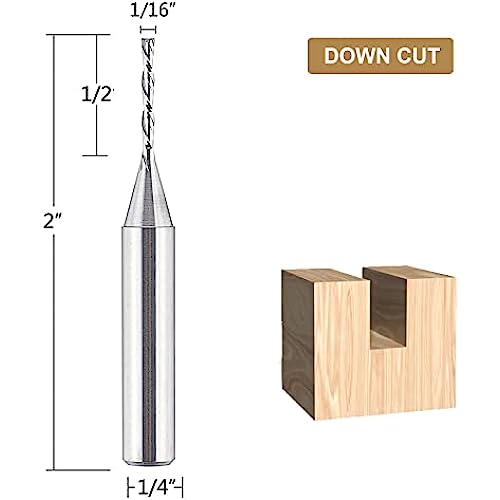

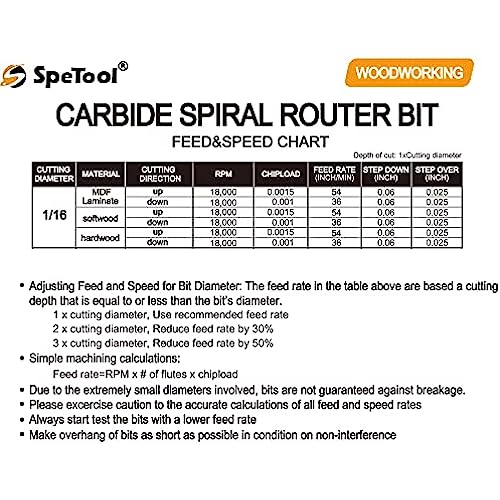

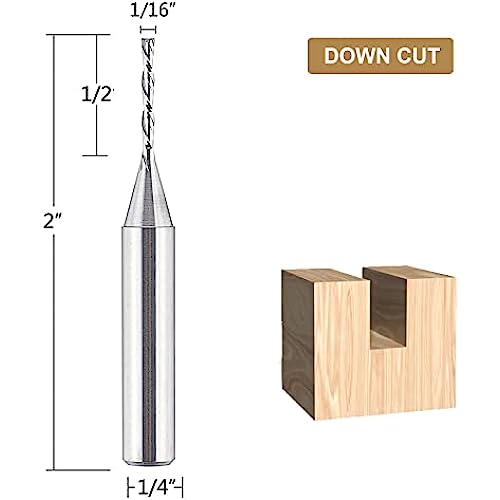

SpeTool Down Cut Spiral Router Bit 1/16 inch Cutting Diameter with 1/4 inch Shank End Mill for Woodwork CNC Machine Tools

-

Miss Eve Ankunding I

> 3 dayWouldn’t recommend, product snapped within first use of it. Have settings on my CNC to have the machine cut 1/16 of an inch each pass and when it got half way through a 7/32” thick cut through; it snapped. The snapped end looked very granular too so doesn’t seem to be made from a good quality mix of metals, or not annealed properly.

-

James D Culberson

Greater than one weekGreat cutter for my CNC projects.

-

Rico Wolf Sr.

> 3 dayI love how detailed this bit helps you be able to get when doing detailed wood projects.

-

Michele L. Adkins

> 3 dayI recently discovered the SpeTool Spiral End Mills and I must say I am extremely impressed with their quality. I have purchased several of these end mills and have been consistently happy with each and every one. I use them in my CNC machine and they have held up well even after multiple uses. The spiraled design provides a smooth and efficient cut, making my machining tasks much easier. Additionally, the end mills are very affordable, making them a great value for their performance. I appreciate that I can purchase a durable, high-quality end mill without breaking the bank. Overall, I highly recommend the SpeTool Spiral End Mills to anyone in need of a reliable and affordable cutting solution for their CNC machining projects.

-

Douglas N. Mitchell

> 3 dayI have used this bit on several jobs so far and if has worked as well as a higher priced bit that I recently dropped and broke. This bit is about 14 dollars less expensive and does a great job, although the feed rate is not as fast as the other bit.

-

HandyBadger

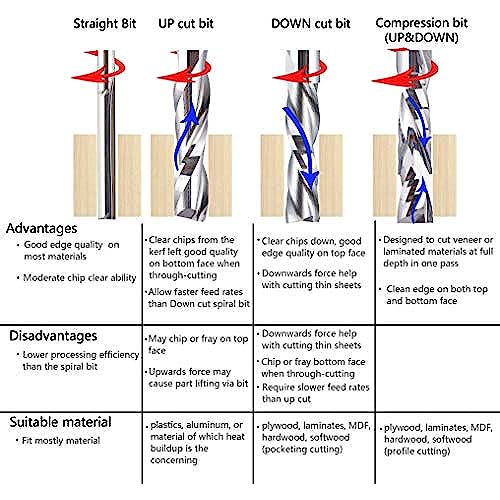

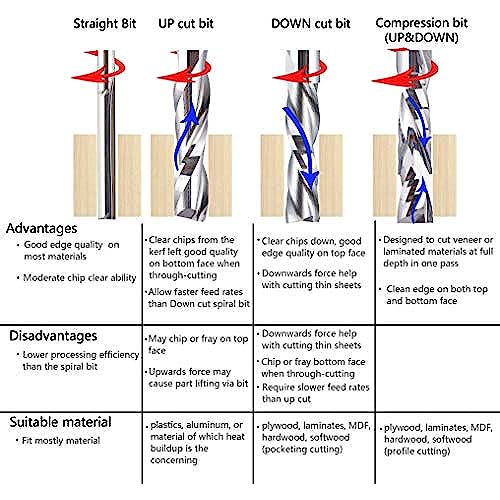

> 3 dayI like to cut signs (and intricate pieces of signs) with my Shaper Origin, and this bit can get into sharp corners much more effectively than other bits (like the 1/8th or 1/4 inch). I’ve started working with 2.7mm plywood, and this bit can easily cut it in one pass, and as it’s a down cut bit, it seems to minimize the sanding needed on the top edge (which is a big deal for me). The bit is a little pricey, but this far I’d say “Worth every penny!”

-

Chris Woolley

> 3 dayWell made and just what I required to finish a project I was completing with my daugther

-

Douglas Ray

> 3 dayIf you do a lot of intricate CNC engraving you will find this to be an often needed and invaluable tool. They are difficult to find, very fragile, and quite expensive considering the lack of durability. I try to use a 1/4 or 1/8 tool for clearing and only use this tool for cleaning up the detail edges. Even then, make sure you are taking VERY shallow cuts, and slow your feed rate down to like 30 per minute. Even having taken all those precautions if your cut takes you through a knot, or you are using particularly hard material like hickory, you will snap these off occasionally. If you are doing custom client jobs, make sure you keep more that one of these on hand and tread very gingerly with them. If you are just doing fine engraving and dont need the straight bit, the 1/16th tapered ball nose is far more durable, and might be a better choice for some jobs. Even for inlays I usually use the tapered bit. You just have to experiment a bit because youll have to make your pockets a little undersize to compensate for the taper. Once you get it down, it a much better way to go for inlays. The taper actually gives you tighter inlays and less gaps. When you do need the straight edges AND tight corners (epoxy fills, for example) this tool is invaluable. I have bought several of these in spite of the breakage, and will continue to buy them.

-

Ernestine Connelly DDS

> 3 dayI have used this to make many signs in pine and fir. It works perfectlly when using oramask as it doesnt leave frizzies or lift the oramask. I am very happy with the sharpness and longevity of this bit.

-

Beth Cochran

> 3 dayNot good quality, broke on first cut. Wouldn’t buy again!