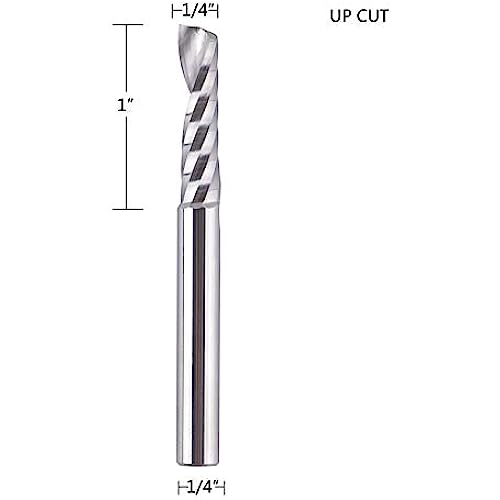

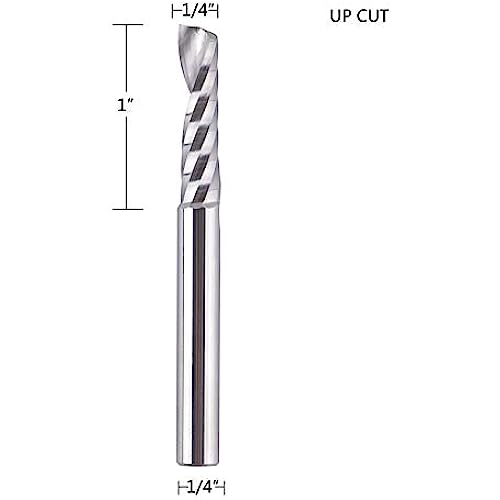

SpeTool Single Flute (O Flute) Spiral End Mill Aluminum Cutter Carbide Router 1 inch Cutting Length with 1/4Inch Shank for Aluminum Acrylic PVC MDF Plastic

-

K. Williams

> 24 hourI used this to cut slots in an aluminum extrusion. It worked much better than Id expected.

-

K. Williams

> 24 hourI used this to cut slots in an aluminum extrusion. It worked much better than Id expected.

-

Erin

> 24 hourLooks like a quality bit, but cut quality is terrible. Not sure if I just got a bad one, but it’s useless unless you want to sand forever.

-

S. Lederach

> 24 hourWorks perfectly on plastic routing

-

Mike M

> 24 hourOnly 1 cut so far but almost no cleanup after first cut

-

Justin

> 24 hourThis cutter has been great for me! I was able to do 14mm depth of cut, single pass, at 1500mm/min with no issues in HDPE. Aluminum I was able to cut 6mm depth of cut, single pass, at 400mm/min. I did get some chatter there, but a finish pass woulda fixed that. If I run a 2nd pass at 0.1mm depth, the finish is very reflective on aluminum, not using air-blast or coolant. Tool cutting ability all depends on how rigid your machine is. This cutter has no problems bogging down my dewalt router. Need a much more powerful spindle to truly push this cutter. Very impressed!

-

Mike M

> 24 hourOnly 1 cut so far but almost no cleanup after first cut

-

todd heath

> 24 hourI run lots of different bits and this brand is one I can for the most part count on as being a decent bit. Not the best but not the worst brand. I have had pretty good luck with the brand but have had a few that didn’t last very long or just not up for the job. They are not super expensive but not cheap ether. With so many choices I can usually count on them. If i am doing a big job or something that is really precise i don’t use them I will use a brand I trust a bit more. Not saying this is a bad brand.

-

Jeff T.

> 24 hourI ran this faster and deeper than I thought I would be able to. Ramp into your material, and use a nice cutting/cooling fluid, and go for it. Nice bit, really.

-

Alexander

> 24 hourWorks with aluminum good