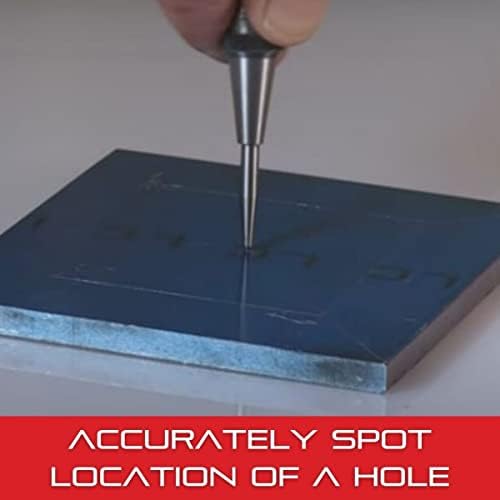

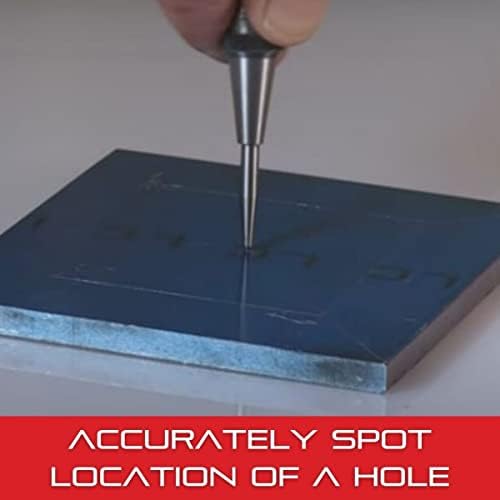

Starrett Automatic Center Punch with Hardened Steel Metal - 100mm Length, 11mm Punch Diameter Tapered Point - 18AA

-

Ms. Jazlyn Bahringer

> 3 dayBeautifully made solid steel center punch. The adjustable action is helpful. Feels like a lifetime tool in your hand. This one is small which I like for getting in tight spaces to mark pieces while they are held against each other.

-

Dale Wennberg

Greater than one weekI wish it was smaller so I could carry in my pocket comfortably. I could not find a smaller version when I ordered, but this one works great.

-

MDCarmel

> 3 dayHigh quality center punch, USA made, type of tool that will last generations

-

Jeffrey A.

Greater than one weekWonderful little center punch. It only rarely misfires and you have to do it again, but normally it is excellent. It is light duty and only good for soft or thin metals.

-

Mr. Stalls

10-06-2025Quality, quality, quality. You get what you pay for from Starrett. Very well made. No complaints.

-

Cade

Greater than one weekThis punch is super high quality, I’ve had it a few months and still working great. But I would say it’s not the best for hard metals, which is what I bought it for. If you are using for marking wood & soft metals (aluminum, brass) should be fine but not so much on steel. I would recommend getting the heavy duty version for about $10 more.

-

Arby

> 3 dayRead the bad reviews. These things seem to have some manufacturing issues. Specifically, the spring over the point seems a bit weak and the things arrive internally dirty with a poor internal finish on parts that slide. However, its easily repairable and just using the unit to break it in will help a lot. Heres how to get it going again. Unscrew the point end and carefully remove the pin, spring and point. Make sure to notice how things are laid out. Clean each component, remove any debris, clean the threads, Use a good lubricant on everything. I like using a dry Teflon type that wont attract dust and dirt. Next, unscrew the top. Careful as there is a spring in there. Now you have to remove the slid inside the top half. Just push it out the top. I used a can of compressed air to blow it out, but a small paper clip would also work I believe. Clean it and the tube. Q-tips are your friend here. Lubricate as above and reassemble. And use it. Wear it in. Youll have to play with the point end adjustment a little, just unscrew half a turn and put back. Itll get smoother and more reliable. Note that on the point end, the point drops in first, then the pin (flat side toward point) and the spring goes on the pin. The smaller end of the spring goes onto the pin first.

-

David Hoffman

> 3 dayThis punch is small, which is a plus, and very dependable. I use it anytime I want a small centering hole. Just push and punch. Well worth getting. The self tapping feature is easy and reliable. Dont know why it took me so long to find this device. No more hammering. Now a simple one-handed operation. Listen for the click and you know you have a made small centering mark.

-

Andrew D.

> 3 dayThis, the 18AA is a little brother to the 18A. Keep in mind that the 18AA has no replaceable tips which can be a good thing as its more rugged. I use auto center punches for aviation rivet removal so they are heavily abused. Starrett auto center punches have never misfired even once for me. Bypass the red punches from the tool truck they are junk compared to a Starrett!

-

hd_dawg

> 3 dayOk for soft metals, needs stronger spring for most steels