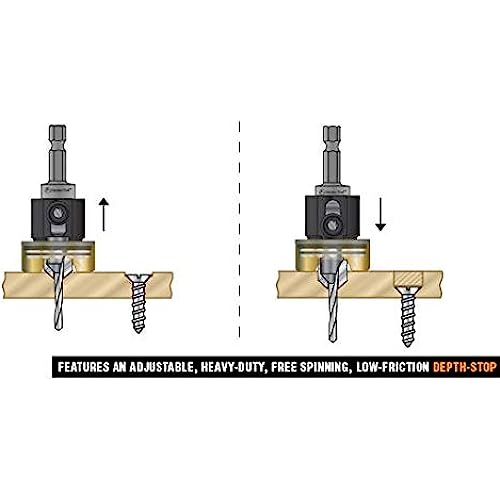

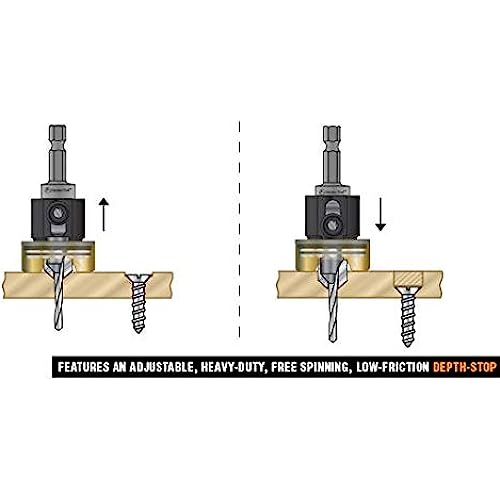

Amana Tool - 55229 Carbide Tipped 82° Countersink with Adjustable Depth Stop & No-

-

Dawn Zieme

07-06-2025Easy to use, easy to adjust, and works great.

-

Bryan

> 3 dayI’m so happy with the purchase, easy to use!

-

MrJD-woodworks

> 3 dayGreat product!! Very practical and comfortable in use. Just a bit expensive

-

Ken

Greater than one weekFirst one lasted 3years - not bad at all in my opinion.

-

Phong Ngo

Greater than one weekI build a lot of painted desks out of MDF and securing them with brads and screws are just the quickest assembly process. But its always been such a pain to work quick but ensure that I dont countersink the screw hole too deep, because then it takes too much work and time to fill, dry, sand, possibly fill again, and repeat. At least on MDF, the no marring feature worked perfectly and setting the countersink to only leave 1/16 of depth when the screw is fully seated is perfect. I can now countersink everything quickly and be sure that Im hitting the perfect depth. Will buy some more of these for the #8 screw as well.

-

Drdave

05-06-2025This just flat out works great! If you are countersinking screws for whatever your project, this is just great. After a few test drills to get the depth of cut dialed in then it’s easy to drill countersink pilot holes and just assemble your project.

-

B. Brown

> 3 dayDrills very easily, very sharp. If you are looking for a countersink, this is the one you want. Theres a reason so many YouTubers recommend it. I wish the price was a little better, but its a quality made product - I think itll stay sharp for a while, so this should be the last one youll ever need (unless you want a different size). If you do a lot of cabinet building, this is excellent. As my dad says You cant work without good tools.

-

Nancy L. Dyar

> 3 dayMy grandson said it was just what he needed and seemed to be please with it overall.

-

Swim fast

> 3 dayVery clean cutting and collar does not mar surfaces. Used it on pre-finished maple plywood and performed flawlessly.

-

CRizzo

> 3 dayI used this on Hardy board and after 20 pieces drill was dull but the countersink was fine. I do have a diamond grinding wheel and sharpened the drill. I put the correct angles on the tip based on the materials I was drilling and it seemed to last an additional 30 pieces. I believe the carbide is a lower standard quality. If I was using this on wood only, I would be very happy with the use and outcome!