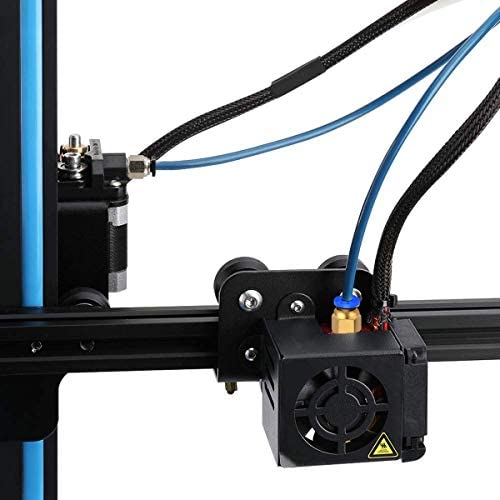

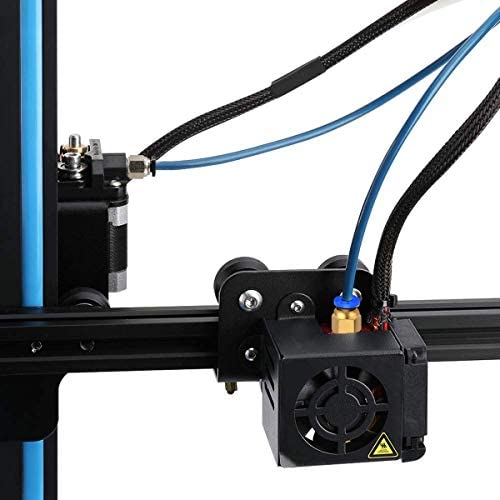

Authentic Capricorn Bowden PTFE Tubing XS Series 1M for 1.75mm Filament with PTFE Teflon Tube Cutter, 2X PC4-M6 Extruder Fitting, 2X PC4-M10 Hotend Fitting for Ender 3 V2/3/3 Pro/CR-10 3D Printers

-

Cody Brown

> 3 dayCapricorn is hands down the best name in printing parts. The accuracy of this bowden is amazing, and it is used by most professionals.

-

Nicholas Hoffman

12-04-2025I will never use another tubing for my 3D printer. Its just that much better.

-

Robert155

Greater than one weekEasy to use, and install.

-

James and Jenny

> 3 dayI really like the tubing and fittings. They went on easily and securely attached the tubing. My only complaint is that it states it has 2 each of the fittings but only came with one set and I cant replace the tubing on my other printer.

-

Garret Bertrand

> 3 dayJust purchased and Ender 5 Plus and the existing filament tubing is lacking. As a 3D Printer, standard tubing lacks the heat tolerance that a Capricorn tube can handle and inevitably will fail and cause you grief. Packing was great with 3 feet of tubing, a cutter to flush cut your tubing which is important that the end of perfectly flat when inserted into the hot end. There were also two connectors if you need them as well as some flair (Cool Capricorn sticker). All in all a great purchase and insurance if you own a 3D Printer.

-

MrFW190

> 3 dayNot quite enough length to make 2 tubes so I can have a spare but it definitely improved my print quality a little bit, especially for flexible filaments since those notoriously don’t so well with Bowden setups. Mine clogged after a few weeks because some of the filament I use isn’t quite 1.75mm enough in its tolerance and just got stuck. So that tells me this tube definitely gets rid of some of the wobbling and bunching up before your plastic gets to the hot end

-

Andrew Compton

> 3 dayIt seems like a ton of people in the 3D printing community recommend this tubing because of its tighter inner diameter spec leading to more consistent moments from the extruder. In theory, and when using filament that is exactly 1.75 mm or less throughout the entire spool, this is very true. However, the vast majority of brands will have a variance that goes a little (or a lot) over that 1.75 mm spec at some point in the spool, which is almost guaranteed to cause a jam with this XS tubing. Even if there is only one spot on the entire 300 meter spool that is slightly out of spec, that is enough to cause friction in the tube and for it to cause a jam. At first, I refused to believe that the tubing was causing the issues and thought I might have an extruder issue. I thought maybe the extruder spring was a little too tight causing it to squish the filament while it pushed it into the tube, making it press against the inside of the tubing. So, I replaced the entire extruder assembly and tried many different springs. No change; my machines were still jamming on a daily basis. I tried many different filament brands from Overture, Hatchbox, eSun, Amolen, etc... and all would, given enough time, eventually cause jams on both of my printers with the tubing installed. I also bought some of this XS tubing for my coworker and he experienced the exact same issue. The issue has only gone away when I replaced the tubing on both of my printers with slightly less tight inner diameter spec of 2.0 mm instead of the 1.9 mm this tubing comes with. Ive been printing nearly non-stop now for four days and have yet to experience another jam. Before you disregard this review with, Well, Ill just make sure my filament is to the correct spec. Understand that, even with the filaments that would measure at or close to 1.75 mm in the first few meters I checked, there was no way I could check every mm of the entire 1 Kg spool. All it takes is one spot to be too far out of spec to cause friction in the tube, leading to your extruder forcing the filament through, causing more friction, resulting in your extruder gear crushing the filament to the point it will no longer move at all. Its a snowball effect of friction. Aside from the inner diameter spec being too tight (which is the whole point of this tubing), everything else was fine. The quality of the tubing was great, the consistency of the tubing itself appeared to be flawless, the cutting tool it came with worked well, and the couplers were a nice upgrade over stock. However, almost none of that matters when the 1.9 mm tube diameter shouldnt be used at all for printing if you care about printing reliability.

-

Nicole

13-04-2025Worked somewhat well, but the connectors were very tight in the printer. Because of this I felt the need to return the product.

-

Jim Perkin

> 3 dayAwesome!

-

Krista Keim

> 3 dayEverything was as expected. However, I did not receive the tube cutter with my order even thought the description said so. I will update if i receive a cutter from the company