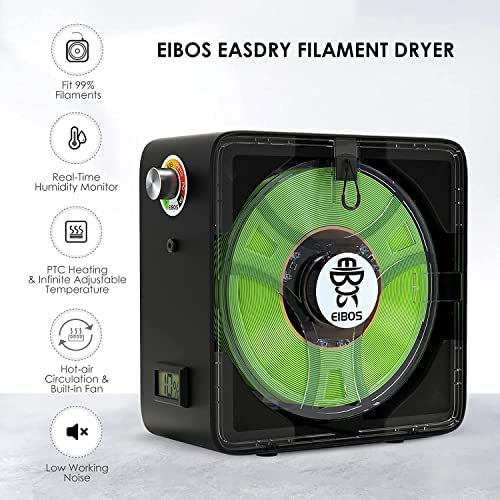

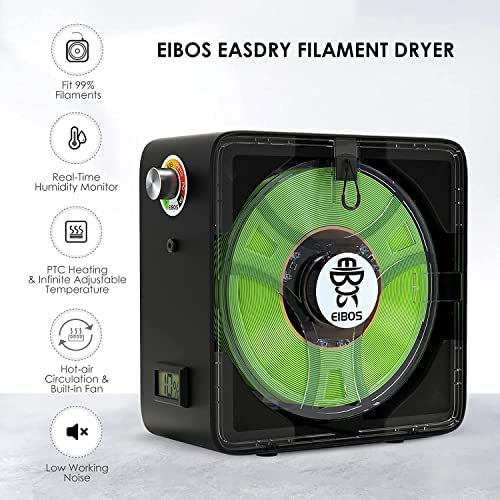

【EIBOS Official】3D Printer Filament Dryer Easdry, 3D Printer Filament Dryer Box with Fan, Adjustable Temperature, Humidity Control & Spool Holder, Compatible with 1.75mm 2.85mm 3.00mm Nylon, PLA, ABS

-

Chase

> 3 dayBought this unit because it does not have a timer or complicated control interface. Works great and dries my filament for as long as I need to, without needing to restart the unit. Doesnt feel poorly built like some other units on the market, has the best heater and fan design Ive seen, and still has room for desiccant packets if desired.

-

Chris M.

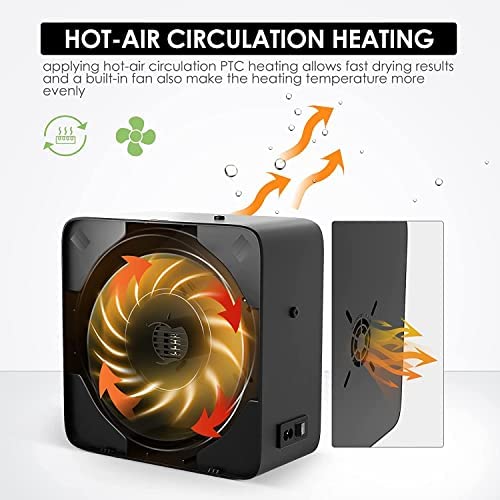

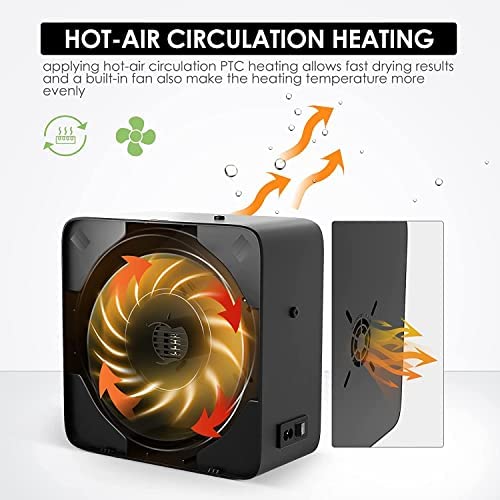

> 3 dayThis is really great for my prints! Dries out my filament really well and doesn’t take up much space at all! - Other filament dryers have a pop up lid that I always felt didn’t have enough heat distribution, so I would always reach in and turn the spool a bit to make sure all of it was being dried. With this I haven’t once felt the need to turn it! - Does take a couple desiccant packs inside to absorb, but has active heat and air circulation! - Digital hygrometer on the side - Definitely has done very well for me with TPU and Nylon! Compact and performs great! 10/10 would get this again!

-

Michael L

> 3 dayWhile this dryer does have 3 holes you can pass filament through with an included bodwen tube it quickly becomes more pain than its worth when trying to print and dry at the same time. Place the vent towards your print bed? Get ready for warping! Trying to dry and print off a new role? get ready for the filament to get twisted! Other than trying to print with it feeding out, its AMAZING at drying filament. I had some brittle filament from the factory that would not print and after having it in the dryer for 8-10 hours it came right back to life.

-

asal moridi

> 3 dayGREAT PRODUCT. EVEN HEAT AND STURDY. BETTER HEAT DISTRIBUTION THAN SOME OF THE OTHER FILAMENT DRYERS. I HAVE ALMOST EVERY OTHER DRYER AND THIS ONE IS UP THERE.

-

Rich

> 3 dayThis is a very nice unit. It’s made very well and has access to feed the filament on 3 sides. The temp knob takes the guess work out of setting as it is labeled for the various different filaments you can use it with. Great job on this!

-

CJ Lamb

> 3 dayThe EasDry I received was obviously used. Seriously obviously. It was missing the protection on the clear pane. It was missing the silicon loop that prevents the spool from sliding. I probably spent 30 minutes looking for the silicon loop thinking it was buried in the box. Starting the exchange process. Will update after I receive a replacement.

-

Isaac K.

> 3 dayI got this filament dryer because it seems simple right to the point and I added what I wanted like my own timing system. This filament dryer is great I am a little confused about the fact that its sticks to the dial switch on the dryer and labels ABS before PETG. It goes from PLA > TPU > ABS > PETG > PC > PA labeled on my Eibos filament dryer sticker. I almost would bet that is a mislabeled sticker because its most likely a dial for temp control. But please support jump right in on this I got no idea if I am supposed to trust that sticker ABS melts after PETG it has higher temp resistance so what am I missing? Otherwise, it functions perfectly! Its not Japanese quality so this is good for a low price. EDIT: Just wanted to add after some more use I am really happy with the purchase the quality isnt my favorite but it keeps the price down. What I really like is this dryer works from the center of the roll really helps push the moisture out on a new roll.

-

Jason H.

> 3 dayThis is a perfect dryer. Easy to use and clear how to operate to get your desired results. The door latching mechanism is my only complaint. I can see it being the first part to fail but it does seal which why the door is hard to remove.

-

3D graphics guy

> 3 dayA few months back I picked up the Sunlu FilaDryer S2 from a kick start campaign. I thought it would be interesting to compare this EIBOS Easdry to the Sunlu. EasDry Sunlu Only displays humidity Robust display with multiple data items direct plug in vs wall wart wall wart for the power No auto off timer Auto off timer Temperature unknown (select by material) Can see exactly the selected temperature Has a fan to circulate the air No fan In general, the quality of build of the Sunlu is better. Notice in the first picture the temperature sticker isnt placed straight on the unit. Neither has great instructions, but the Sunlus are just a bit better Testing: Here it gets a bit interesting. I put a spool of PLA into each dryer and ran the driers for 3 hours. The EasDry started with the display showing 45% while the Sunlu showed 55%. After the 3 hours the EasDry showed 10% while the Sunlu showed 74%. Before and afters captured for both units in the photos. Seems like the Sunlu evacuated the moisture from the filament (dont know where else it would come from) but the moisture remained in the unit whereas the fan in the Easdry evacuated the moisture. So it might be important to remove the filament from the Sunlu right after drying so it wont reabsorb all that moisture while it could remain in the EasDry. Both units have a filament feed port so filament can be used for printing while being dried of just after drying. In almost every way I think the Sunlu is superior, but not expelling the moisture is a pretty big ding. In practice I will use both, but will use the Sunlu only for drying (and immediately removing the filament) and the Easdry for drying and feeding to the printer. Below is the link to the Sunlu for comparison. https://www.amazon.com/Filament-FilaDryer-SUNLU-Large-Size-Real-time/dp/B09PNDD5TT

-

Erik

Greater than one weekMost filament dryers do not have a fan, this one does. Seems built very well.