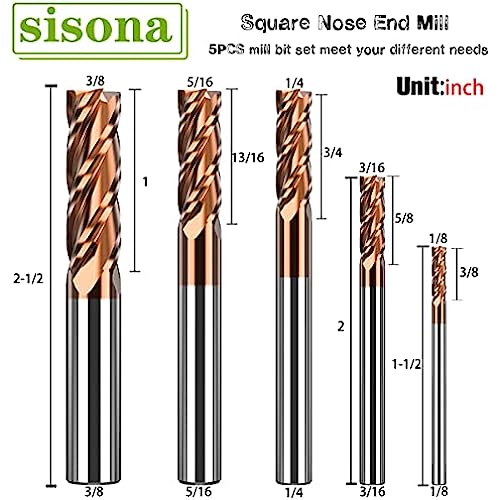

sisona 1/8 3/16 1/4 5/16 3/8 Carbide End Mills Set - Solid Carbide (Tungsten Carbide + Cobalt) - 5Pcs 4 Fulte CNC Mill Bits for Steel - TISIN Coated

-

Bless The USA

> 24 hourI have been needing to elongate the slot on this bracket so figured would give these a try. I chucked one of them up and went to it. I was not slow or gentle on it ether. I only made two cuts and it loved it. No complaints from it at all and with no lube either. I wanted to see just how well it would do when rushed and did just fine. Kindof surprised for a no namer. I know that will need to run for much longer to determine its true lifespan but for the price I cannot complain. I have a budget and cannot always get the best out there and these fit the bill. Hope this helps and thanks..

-

Jeff N

> 24 hourThese Sisona bits do cut through thick solid steel pipe and thick ceramic AFTER using a different kind of drill bit to start the hole. You CANNOT use a center punch or anything on ceramic though. And a center punch isnt going to go far in the solid steel pipe I tried to drill through. HERE’S WHAT HAPPENED IN THE STEEL PIPE I got two sets of Stubby Drill Bits for Thick Steel at the same time. The largest NordWolf Bit wasn’t big enough, but it did easily stay centered on a Very Thick, Very Heavy Steel Pipe, and drilled through the first side like hardwood. Then I was going to try the same size bit in this set on the other side and it absolutely would NOT stay, no matter what I did. No matter how strongly I held it or careful I was, it kept walking and wandering off to the side. I tried a lot of times, and it would Not even START to drill a hole. I really wish I could have actually got a hole drilled with one of these bits, because the NordWolf only stayed sharp for the one side. It went completely dull on the very next side. Didn’t even drill two holes. HERES WHAT HAPPENED IN THE BOTTOM OF THE LARGE CERAMIC POTS Two large Ceramic Pots outside needed holes in the bottom before it rained. Again, the NordWolf drill bit was too dull after one use to even start the hole, so I used the next size down. And again, these bits absolutely wandered and walked away constantly, even from the starter holes I made!! I finally finished, but my cordless drill worked harder than ever before. I hope its OK.

-

Sarah

> 24 hourWe’ll packaged and good quality

-

JamesF

> 24 hourI must say these are a lot better than I anticipated. And I cut through some pretty hard material and they’re still sharp.

-

Dave Evers

> 24 hourI use these with my Grizzly mini-mill - they are just the right size for a light duty machine. Useful range of sizes, and economical. Recommended

-

Miz J

> 24 hourI get it these are specialized tools. Not everyone has a milling machine. Well, I know someone that does and I have some parts that will need milling. Since I know I want him to do it as a friend, I figured this would be a nice trade. These are Tungsten Carbide and cobalt. We will be cutting a steel hitch that is 2.5” and needs to be milled to 2.0”. While we have not used them yet I am told that this is a good set and exactly what is needed to do the job. As far as price goes, I am no expert on these. I see prices for way less to way more. Once I see them cut the value will be in did they work as expected. When I have time to go over and he has time to mill, I will update my review. For now, not having much to go on except my friend the expert’s word I think this is a good set and recommend them.

-

L&S

> 24 hourI would call these a good value for money. They showed great durability in a 1952 Bridgeport mill cutting 304 stainless steel.... and I cut a lot of it on a single cutter. Good job, I will buy more.

-

dallinna

> 24 hourMy wife ordered this for me through Amazon vine, so this is her husband leaving the review. Good quality carbide for the price. From my typical suppliers, these would have cost a lot more.

-

Jay Bird

> 24 hourTested the 5/8” cutter in hot rolled steel, was able to do a full width cut at 2mm depth with a feed rate of 480mm/m on my CNC converted HF mini mill. Surface finish was excellent given the rigidity (or relative absence!) and I was very pleased with the speeds I was able to achieve - quite aggressive for me but felt I should put the cutter through much more than I ordinarily would for the purposes of this review. These cutters are definitely on my must buy list. Ran it dry and did four faces on two 1/2” x 3/4” x 4” pieces. Photos show finish from roughing operation and the blue chips it produced with no sign of cutter deterioration after removing a total of 1/4” over a length of 16”!

-

Brendan Y.

> 24 hourI finally got a chance to try out these endmills recently, and so far theyve been working great. Ive mostly used the 3/8, and its been perfect for my uses. I used it with some 1018 steel, 6061 aluminum, and O2 tool steel with my manual mill and it doesnt have any signs of wear yet. I hogged out some material on the piece of 1018, taking quite heavy cuts just to test the performance, and it worked well and cut like butter. I measured the grind of the flutes, and its only a few tenths small. I was able to hold a thou tolerance very easily. For the price of this set and the use Ive gotten from it so far even with only one of the endmills, Id say its 100% worth it. Ill update this review later on if I get a better scope of the durability or if any issues happen.