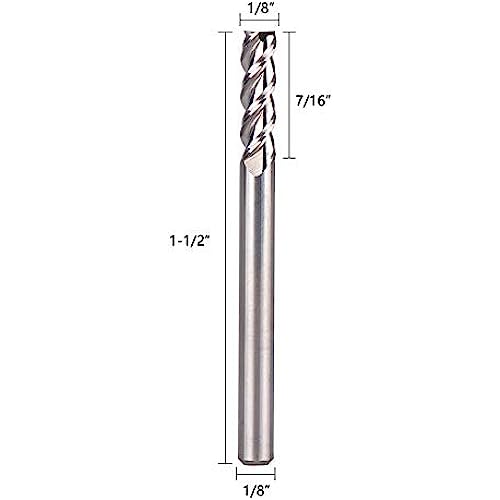

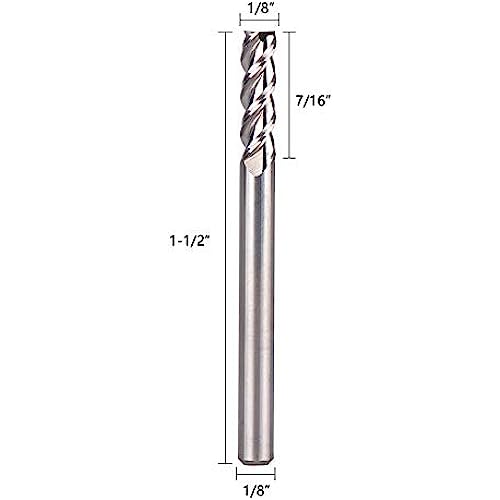

SpeTool 1/8 End Mills for Aluminum 3 Flutes CNC Spiral Router Bits for Aluminum Cut Non-Ferrous Metal Upcut 1.5 inches Long 5 Pieces

-

Prof. Sofia Bode IV

> 24 hourMilled several inches of 1/4 deep slots in aluminum, worked very well and didnt break.

-

Jeffrey Fox

> 24 hourPerfect for the price

-

Mary

> 24 hourThese bits are absolute junk. They break at the slightest side load when cutting aluminum. Might be good for foam or soft wood, but NOT cutting hardwood or aluminum. SAVE YOU MONEY!

-

Frazier

> 24 hourCut right through aluminum easily as long as I dont do something stupid in my g code.

-

Boris

> 24 hourFWIW, I used it in my CNC mill (sticking out 1 from the collet) with the following feeds/speeds and it cut perfectly: 3000 RPM 10.4 in/min feed .036 depth of cut .050 step over Climb cut

-

Sandy

> 24 hourIt works great on acrylics. But not aluminum. It broken after I used it on aluminum.

-

Phil

> 24 hourWell made end mills. Able to fine cut names in heart boxes for Christmas gifts.

-

Robert Charles

> 24 hourPoor quality

-

Josh Yost Sr.

> 24 hourYes Great product worth the money and has done its job well.

-

Jamie P.

> 24 hourI just got started using my SainSmart desktop CNC but needed an Upcut End Mill for an aluminum project. These end mills have done a great job chipping away at my project. The construction of the desktop CNC is a bit lacking so I can only cut 0.005 in depth per pass. Ive run one of these end mills for 100hrs or so will no real change in cut quality. I did break one end mill when a part came lose during a cut but that was my own fault setting up my material improperly.