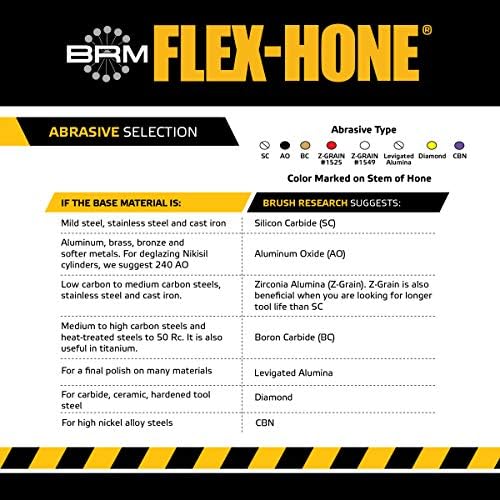

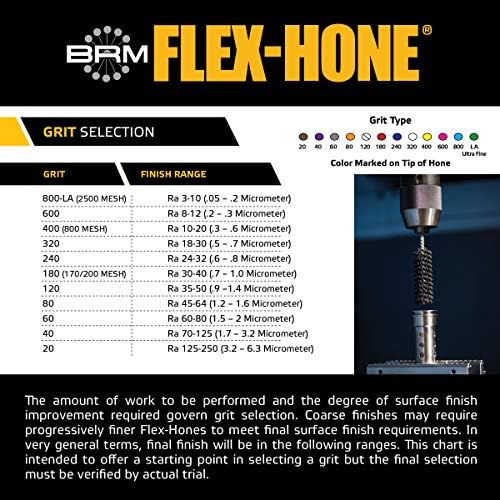

Brush Research FLEX-HONE Cylinder Hone, BC Series, Silicon Carbide Abrasive, 3 (76 mm) Diameter, 240 Grit Size

-

Vintage Motorcycle Repair

> 3 dayI have six of these now, and I buy a new one if I need a size I dont have. They work perfectly to take the glaze off of a motorcycle cylinder before installing a new piston and/or rings. They are sturdy, and last a very long time if treated well. Pro Tip: Dip them in transmission fluid before honing.

-

carpenter

Greater than one weekThese are very easy to use Time will tell how long they last

-

Matt

Greater than one weekUsed this for refinishing a plow piston cylinder. A lot of people complaining about the price but this is much cheaper than any other available option, whether sending out to get machined or buying and actual hone setup for at home.

-

MD

Greater than one weekUsed this for my Predator 212cc go kart build, where I was swapping to a flat top piston for additional compression. While the cylinder didn’t look bad to begin with, this hone made it look great. I coated the hone in oil and utilized it for around 30 seconds per the instructions. Can’t wait to use its again on the next build!

-

Michael E Stora

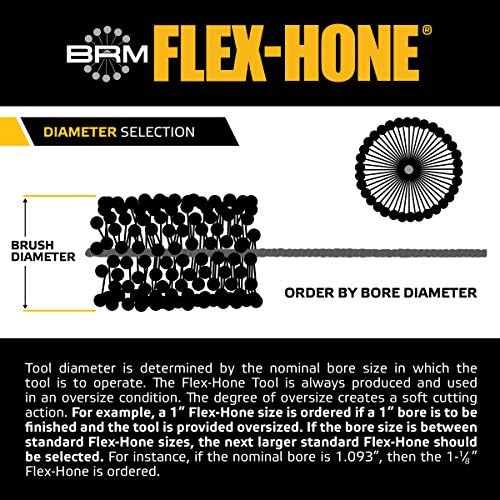

> 3 dayIf you are only a tiny bit over the nominal size do not follow the instructions and go up one size. They are oversized to begin with (my 1 1/8 hone being a few thousandths shy of 1 1/4). I bought a 1 1/8 hone to remove the seam from 1 SCH40 pipe and open it up from 1.03 to 1.06 so that 3/4 pipe will telescope in structural applications. I also intended to use it to open up 25mm aluminum C-cell flashlight tubes to fit 26mm LiFePO4 cells (1.026). I am hoping that after breaking in the hone on the steel pipe I will be able to start it in the aluminum tube without damaging the end. I think in both cases I would have been better served in not following the instructions and buying the 1 hone instead.

-

Matt

13-06-2025Used this for refinishing a plow piston cylinder. A lot of people complaining about the price but this is much cheaper than any other available option, whether sending out to get machined or buying and actual hone setup for at home.

-

BigNaz

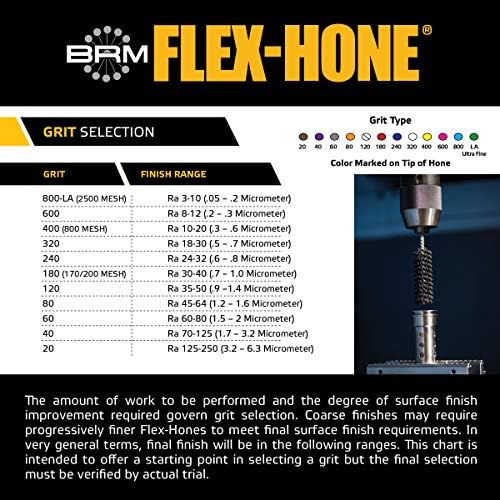

> 3 dayUsed this to hone both cylinders of a 22 hp Briggs VTwin lawn tractor engine that needed a new connecting rod, a new piston and 2 sets of rings. Honing the cylinders is needed to allow the rings to break in and seat properly. Since I don’t expect to do this regularly I was between a cheap set of honing stones for around $20 and the Flex hone which I’d seen on YouTube and was selling on Amazon for $37. The reviews on the honing stones were terrible (cheaply made and inconsistent result) and the flex tool reviews while not numerous were mostly positive. Several excellent YouTube videos by the manufacturer and a call to the seller about whether the 3 inch (180 grit) tool would be good for my 2.96 inch cylinder convinced me it would be worth the extra cost for the Flex hone tool. What a FANTASTIC result in less than 10 minutes to do both cylinders following the video instructions of coating the tool with clean oil and moving in and out of each cylinder for 1 minute. Perfect cross hatched pattern on both. Great tool and good value considering the $200 of parts and many hours of labor to complete this project.

-

Hollywood

> 3 dayExactly what you need to prep a new Nikasil cylinder for new rings. This will remove material quickly, which is what you need to set in a nice hash pattern in Nikasil. However, you only need a slow speed (low gear on most drills) and only 3 or 4 oscillating strokes. Good luck.

-

Tom

> 3 dayI have personally relied on products from this company for a very long time in a professional setting. As far as ball Hones go Flex-Hone is the best and has been. The quality is top notch and the number of sizes they make are unequalled by any other company

-

Mike

> 3 dayPurchased 76mm for honing an old ATV cylinder. Some WD40 and several passes later the bore is cleaned up and has a nice surface for the new piston rings to seal in. Cleanup is easy with carb or brake cleaner. Make sure to get the right size hone for your bore!