Buffing Polishing Pads, SPTA 5Pcs 6.5 Inch Face for 6 Inch 150mm Backing Plate Compound Buffing Sponge Pads Cutting Polishing Pad Kit For Car Buffer Polisher Compounding, Polishing and Waxing -SQMIX65

-

Al

> 24 hourFirst of all, I dont have loads of experience polishing cars. I was using the wool pads that came with my Makita rotary polisher, but didnt care for the poof factor of the hairy wool - I felt like I wanted more control in tight areas to really see where the pad was meeting the paint. I also didnt want to spend a ton of money on pads because I wont be doing this frequently at all. Suffice it to say, using these foam pads has been an absolute joy! They worked waaaay better than Id hoped, and they didnt shred themselves apart like I feared. Theyre nice & squishy and easy to clean, theyve stayed soft, and even after hours of use Im not really seeing much wear in the little cube slice pattern on them. Outstanding!

-

tmb

> 24 hourThese buffing pads awe well worth the money . I highly recommend this product .

-

DEF088

> 24 hourThey work but are small, and probably wont hold up long, but they will get the job done and they are not expensive.

-

Duderous

> 24 hourWorks great with Meguiars!

-

Brett

> 24 hourHi. I am a hobbyist who cleans a lot of other people’s classic cars of various conditions through out the year. I’m on my first experience with these pads. It fits my Rupes LHR15 Mark III to the tee. I have used the yellow pad and white pad. The yellow has a good cut to it with M105 to remove 3000 grit sanding. The white pad with M205 has a good finishing ability. So far I’m pleased. I will order again. They set us cheaper than 2 pads of what is was using. And do a better job. Again I’m pleased and I’ll order again. Directly, I’m comparing them to the chemical guys hex logic pads which are awesome too. But like having all the pads so I can choose how aggressive I want to be with the cut of the pad. I cannot comment on on durability or easy to clean as I have not so so yet. But I’m assuming it will be Like others. Some pad cleaner and a good hand scrub then in the washer they go.

-

Andreas K.

> 24 hourMy harbor freight purchased pads only lasted 2 washes, as the Velcro pad off after washing with a mild soap and rinsing. These are holding up better. Only used one pad so far, and it has held up 3 washes so far with zero indications of it coming apart. As for the polishing, it does as advertised too. Good purchase for the money…so far

-

goose

> 24 hourUsing these on motorcycle pain and was concerned about the hardness of the pads at first. Started using a less aggressive compound just in case and so far so good. Its also nice to have a box that they can all fit back into (rather than just plastic bags...

-

Halfback802

> 24 hourThe pads were to too tough even for the one that was supposed to be for polish only

-

Car Guy

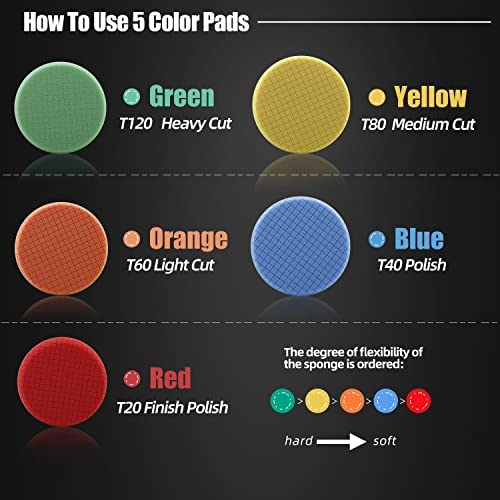

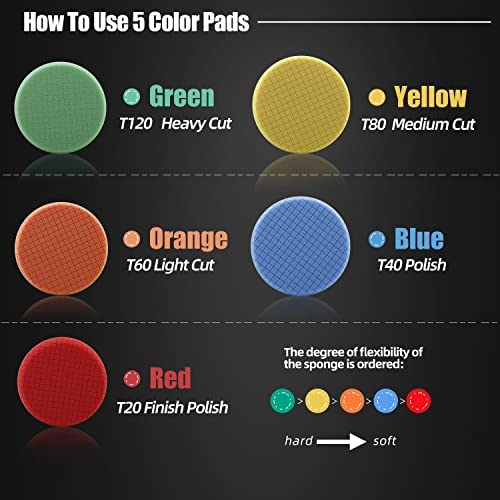

> 24 hourThese pads worked fine when I used them to remove light scratches from my paint. The cut of the different color pads is not marked on the top of each pad however, so make a note of them before you throw the box out. Other than that, no gripes.

-

Steven Moore

> 24 hourPads are just as advertised