Buffing Polishing Pads, SPTA 5Pcs 6.5 Inch Face for 6 Inch 150mm Backing Plate Compound Buffing Sponge Pads Cutting Polishing Pad Kit For Car Buffer Polisher Compounding, Polishing and Waxing -SQMIX65

-

Mike T

> 3 dayUsed it to do my 2016 WHITE FOCUS ST. Came out pretty good. Used a orbital sander lol. I mean the pad was a little big for being a 5.5 but worked pretty good. Paired it together on setting 4-6. Didn’t burn the pad like others said. Did the car in less then a hour and turned out amazing.

-

Robert A. Gulbrandsen

> 3 dayComparable to Chemical Guys product for less money.

-

Halfback802

> 3 dayThe pads were to too tough even for the one that was supposed to be for polish only

-

Capn Gary

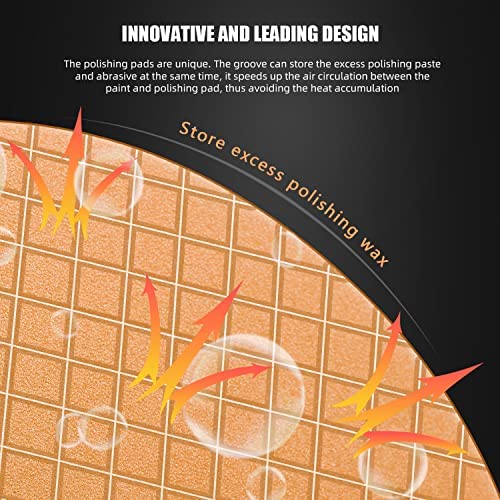

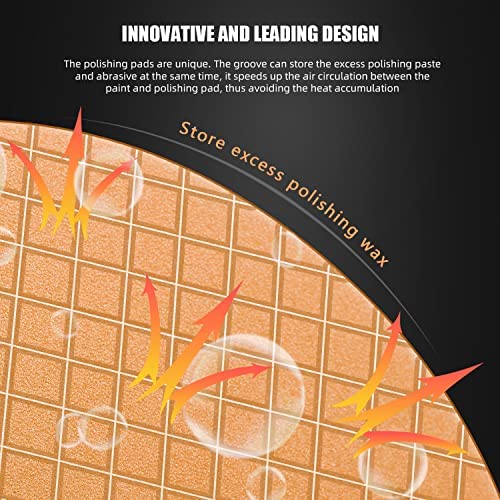

> 3 dayBought these to compound my sailboat hull. Overall a decent value. The scoring in the pads works well to hold the compound/polish. However the pads werent as durable as I would have liked.

-

DEF088

Greater than one weekThey work but are small, and probably wont hold up long, but they will get the job done and they are not expensive.

-

Delmig

> 3 dayEs la segunda vez que los compro para Colombia , los primeros duraron mucho y de muy buena calidad esta vez los pedí más grandes de 7 inch satisfecho con el producto buen precio buena calidad

-

Arlen

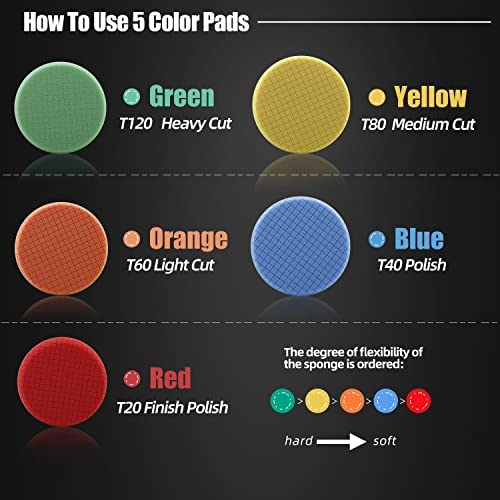

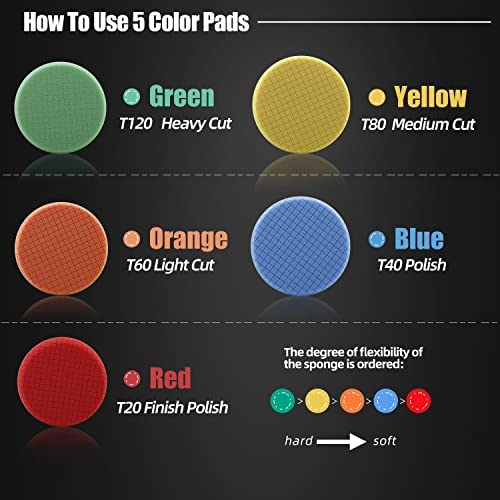

> 3 dayThese pads work extremely well when used in steps from course to ultra fine polishing. Just wash them when finished with soapy water and set them aside to dry and they are ready to use for your next polishing job.

-

AdMan

> 3 dayI am carving through a 1995 Catalina 250 Sail Boat Top Side White Gel Coat. The oxidation is so bad it looks like sand paper. I am using Meguiars 105, 110 and Flag Ship Wax. The 110 stays wet longer but both 105 and 110 cut the same pretty much. These pads have the ability to run for a long time without cleaning and take a lot of pressure which is what it takes to bear down through the oxidation I am fighting through but they do stay together. Be sure they are dry after cleaning I had the back come off one but I know it was damp and my fault. If you want a pad that holds together well and keeps cutting with constant cleaning these do just that. My steps for BAD Gel Coat were 1. use StarBrite Deck Cleaner, Muratic acid ( dangerous stuff be careful) for the lime deposits from our Limestone heavy lake then rinse thoroughly. The Deck Cleaner with patience and a terry cloth rag can remove some oxidation but it takes time however works in bad spots that are hard to get the buffer in. I am using the Bauer Harbor freight 79 dollar DA buffer special. Its a beast, you can lean on this buffer and it just keeps taking the punishment. Once you have your Yellow or Orange Pad on I prefer to drip the 110 on to the surface then use a small tooth brush to rub it into the oxidation. I know this sounds strange but you will be sure to work the Compound into the Gel Coat. As soon as you do that put your DA on speed 3 which is pretty fast but land the buffer pad on the surface next to the area to make it stop spinning then walk into the compound you just tooth brushed in and go slowly with firm two arm pressure and work across the surface. You will do 90% of your cut pass with this since all that material is brushed into the surface and working at full stuff, full pressure and slow speed which I have found to be really effective. I finally realized that you have to bear down on the buffer to get the compound to cut effectively. You will be amazed at the results if you follow these steps. My Gel coat was gone any one else would have got out the 3000 grit sandpaper but that is risky. Compounding seems to have a tendency to stick to the oxidation so you leave the good gel coat alone that has been cleaned. Finally after you are starting to see some sparkle wipe it all down with a micro fiber rag then by hand rub the Marine Wax into the surface being sure to cover all the shiny gel coat you just compounded. Do not worry about it drying a little. Now put your buffer at 3 to 4 and use moderate pressure and buff the surface and keep going until you see the incredible shine come through. Putting some pressure on this at first is a good idea since the Marine Wax has some oxidation removal ability which smooths out any marks the compound left and can still take some oxidation micro spots out. I like to then finish with very little pressure speed setting 3 to final super buff the finish ( same yellow pad). Its awesome. Sorry for the long post but I am sharing how I got through a lot of heavy ( 15 years+ worth) of oxidation and these PADS and the Meguiars products got me there.

-

Charlie

> 3 daybuffing car so far works as it should wood have given five stars but do not know how long they will stand up it looks like they will

-

C7corvette

> 3 dayThe buffers worked great