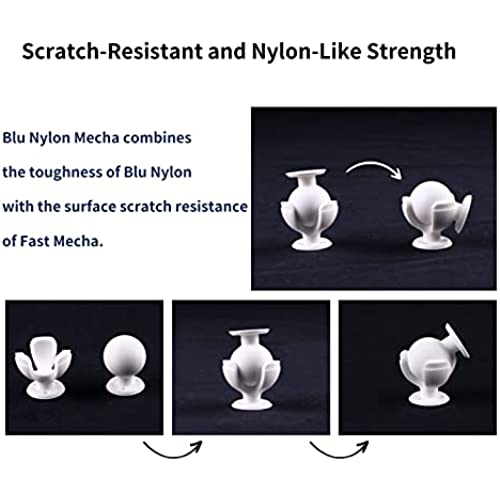

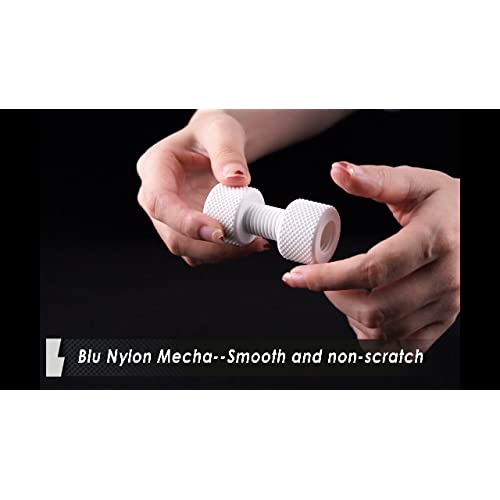

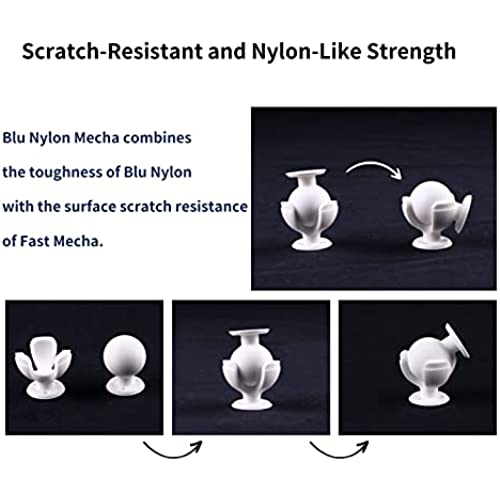

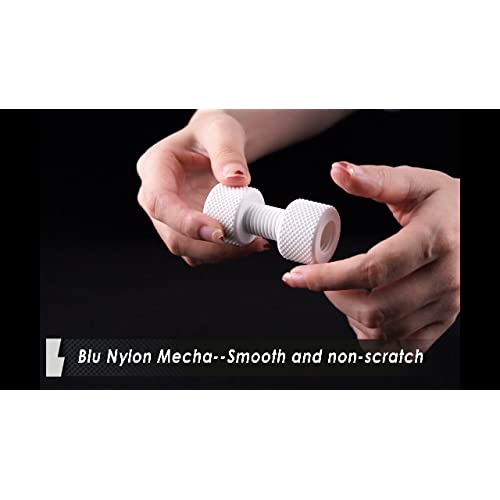

Siraya Tech Blu Nylon Mecha - Tough 3D Print Resin, Scratch-Resistant, Nylon-Like Strength & Precision, High-Resolution 405nm UV Curing LCD DLP 3D Printer Compatible, 8K Capable (1kg, Nylon Mecha)

-

Dr. Alejandrin Runolfsdottir

> 3 dayThe resin is so thick, that when my build plate lowered into it, the torque on the motor was maxed out and it kicked backed two times very quick The viscosity is practically like pushing into a solid. 75 degrees F here and this stuff flows INCREDIBLY slow. It seriously is so thick that the build plate has enough resistance just lowering in, that it prevented my machine from moving down, maxed out the motors torque You must have to preheat this resin or put on exposure delays to start. My builds failed at first because the resin cannot flow in fast enough when doing initial layers.

-

Margaret

> 3 dayFirst resin I tried, did everything as instructed (test/validation prints) and had subpar performance. My prints were failing to come out clean, I tried multiple support styles, auto supports, and after wasting almost the entire bottle I purchased a few other resin types ( not siraya tech). Every resin Ive tried besides this one has printed so perfectly my opinion of 3d printing has changed entirely, this resin was so horrible in every possible metric (besides strength) I wanted nothing to do with 3d printing. I blamed myself for lack of experience in my first print failures, but now that Ive tried multiple other resin brands I realized it wasnt my fault for the horrible print quality this resin delivers. No matter how nice my test prints turned out the actual prints I needed were distorted, edges bleeding, weird print lines, couldnt be more disappointed with such a highly rated product. Do not buy this as your first resin!!! Start with something that actually works before this headache causing stuff.

-

R. Meyers

> 3 dayI was looking for a resin to make structural parts with, and this does a great job. At a thickness of 1/8 inch or more, its very sturdy, approaching the strength and smoothness of injection molding. I had to put it in a vise and bend it with a channel lock to break it. At thinner gauges, its flexible enough to bend 180 degrees before breaking, and can be stiffened by mixing with more rigid resins to get a mix of stiffness and flexibility. But you will need a small heater to work with this resin well, as it requires 30°C to get it runny. I am using this heater https://smile.amazon.com/gp/aw/d/B07573FKSG?psc=1&ref=ppx_pop_mob_b_asin_title plugged into a digital thermostat https://smile.amazon.com/gp/aw/d/B01I15S6OM?psc=1&ref=ppx_pop_mob_b_asin_title to regulate the resin temperature. Youll need to find a way to attach the heater and the thermostat probe underneath the red cover, and warm it up 5-10 minutes before printing. I attached the heater at the top end of the z axis on the right side, out of the way of the build plate, and attached the temp probe to the left side. Just set the thermostat to turn on at 30° and off at 31° to keep warm. Easy.

-

Tazoo

> 3 dayCompletely amazed at this resin. Tint of Blue/green and sticks to the build plate really well, get a stronger removal tool you will need one. The pictures are of a model print at 0.05mm layers.

-

Tre

Greater than one weekElegoo Saturn user Like most reviewers of obsidian black I wasted a lot on failures. Which is unfortunate, as I need this resin for a project and its not the cheapest. Finally I found one user who left a review with the settings Siraya tech sent them to try and it worked! They need to update their site with those settings! One issue I had as well was with supports. For heavy/denser prints youre going to need to increase the diameter of the tip of the supports and move them so the tip is at least halfway inside the print area. You may have to do a little filing to smooth the nubs, but its worth it to keep your prints from falling away/disconnecting from supports. It is not a light or pleasant odor; it stinks! Respirate and ventilate! Other than that very good performing resin. Can take a lot of bend stress but not the most impact-resistant. Can take a bump, but I would not recommend for any application subject to multiple direct strikes.

-

MikeyFTL

> 3 dayIve had a hard time finding a resin that can hold up to stress in a project that has moving parts. Most resins are brittle and snap under moderate stress. I added Tenacious to toughen them up, but that caused the part to flex too much and eventually broke as well. In a last ditch effort I tried Blu and couldnt be happier with the results. Its a super thick resin, like honey. The smell is not as bad as Anycubic resins and it stuck to the plate beautifully on the first try. The part I printed is only slightly flexible and doesnt lose its shape or break under pressure. I normally clean my prints with iso and water, but water will make the print look cloudy, so you may want to avoid water if you want that transparent look. If this resin came in black or white it would be the only resin I ever use.

-

John Doe

> 3 daythis product is one of my favorite resins and honestly gives me some of tge best prints ive ever had

-

D. Skye

> 3 dayI really like this resin with my Anycubic Photon. It prints well and easily. It bonds to the build plate quite well which prevents the failed prints Ive had with other resins caused by the print detaching from the build plate. Prints are a little flexible and quite strong compared to most resins. This resin doesnt create the most detailed prints possible, but when I need a part thats durable and printed to a certain dimension, Siraya Blu is what I go for. One small catch: this resin is best printed at 30C. That may require the addition of a heater to your printer. I added one to my Photon along with a temperature controller for just a little time and money.

-

Justin Hawley

Greater than one weekI would one hundred percent recommend this resin for functional parts. The parts are incredibly strong and arent brittle at all. Not sure I would recommend it for miniatures or busts but I have seen people get decent results. Removing supports is generally harder than I have experienced with other resins because the stuff is so damn tough and flexible. From a usability standpoint it can be a little tough to work with. It doesnt smell that bad. It has a kind of almost minty smell but the smell is really strong and lasts a long while. The resin itself is incredibly sticky and oily in its liquid form and is difficult to clean up. Usually with most resins I am able to wipe most of it away from the vat and spray the rest off with a small squirt bottle of IPA. This stuff requires a lot more labor to clean up. I havent had a lot of experience with this resin yet but using a compliance matrix test print I arrived at 3.75 seconds exposure per layer for this resin and all other settings default

-

Steve

> 3 dayI was mixing to get something like ABS but stiffer. Blu Nylon Like is exactly what I needed.