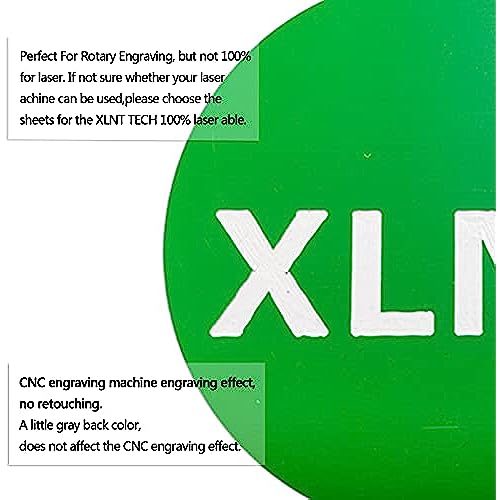

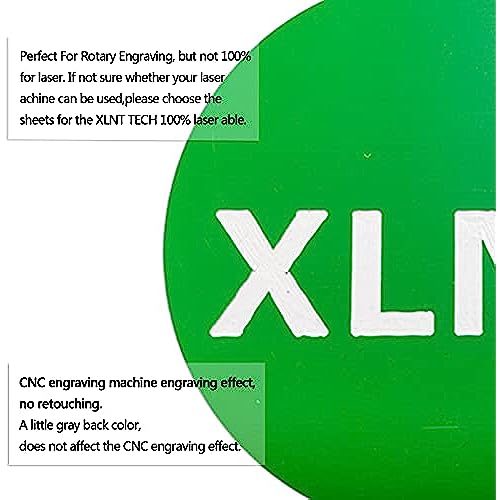

XLNT TECH Engraving Double Color Sheet (7 x 11“ x .040”, 12 Pieces & 12 Colors) for Interior Signs, Badges.

-

Andy Canable

> 24 hourHavent got to use them yet but they look fine!

-

Christine Margaux

> 24 hourThis engraving plastic works as well in my laser as any other I have tried. It comes with a plastic protective film on top. You want to leave that film on when you cut and then carefully remove it afterwards as it will keep your material from getting all sooted up. Raster engraving will not leave a smooth surface. Ive tried the stuff from Trotec laser and I didnt get a smooth raster finish with that either. What does work is cutting, and its cousin - vector engraving (which is just cutting, but with less power and faster so it doesnt go through). The top coat on engraving plastic is REAL thin, so youll likely find that the fastest movement and the lowest power your laser will do will be enough to leave marks. THE MOST IMPORT THING IS SAFETY!! I run a Middle School makerspace. The most important part of onboard training (Which i do for each and every tool in the space, for each and every student that comes in) is how to work with a tool safely. Lasers work by cutting things with heat, so a risk with laser cutting is always FIRE. Ive had fires start when cutting cardboard, paper, foamcore, and rubber. You should ALWAYS have a fire extinguisher next to your laser cutter. You should always check before you start cutting that you know where said extinguisher is. You should NEVER leave the laser while its running. Watch it work! Also, you might keep a spray bottle full of water near the laser. Most laser fires can be extinguished with a few swirts of water and thats a lot easier to clean up than a fire extinguisher. You will need the following upgrades on your laser to use this material: 1) FUME EXHAUST: Folks, having an exhaust to take your fumes outside is super important no matter what you are cutting in the laser. Cutting WOOD in the laser results in ultrafine (<2.5pm) particles that are hazardous to your health. This stuff is ABS plastic, read up on burning ABS - it will release formaldehyde which is REAALLY bad for you! Dont skimp out, get a fume exhaust system in place. 2) Air assist: ABS is known to be a fire-prone material when laser cutting. Having an air assist is really important for blowing out most fires that will start when cutting this material. Again, dont cheap out, an air assist costs less than a new laser cutter or house.

-

Brent

> 24 hourAs a new hobbiest I didnt really know what I was doing. When I purchased this product I didnt know I really the gem I found. This is a great product and at this price point it allows hobbiest to experiment and get better at the craft.

-

Frank Epstein

> 24 hournot as described in title. The item title says .06 thick, but I measured each and every one and they are only .04. They are, however, easy to to do the score and bend to snap into smaller pieces. take a flat edge, carefully gently slide the edge of a box cutter to score, or use something like a manual slide the blade thing with mounted blade, about 10 times to make a groove, bend it against an edge to break, snapping into smaller pieces, then use a knife to trim the edges if any bits are sticking out. so to grade for star ranking: 5 stars for great sampler pack of different colors. 3 star for each sheet that is NOT .06 thick but instead .04. good enough for name tags, but still not as described. all 12 that I got were only .04 so that is 36 points for all 12 sheets + 5 points for variety = 41. and then divide that by 13 (counting variety as 13th thing to grade on) to get the average = 3.153846153846154. rounding that to nearest star vote choice means 3 star.

-

Macgeek

> 24 hourI purchased a Glowforge laser - and have been experimenting with it using plastic / wood / etc, and THESE acrylic sheets give hands down the absolutely BEST results, the two tone really shines thru, turning your project into one with PUNCH!!! - they are a bit pricey but worth every penny! PS: I would have posted a photo, but all the stuff I do has peoples names or corporate logos and I dont think they would approve.

-

Sigmund Mann DVM

> 24 hourWe used our 50W laser engraver at the lowest setting, and the results were terrible. The colored film bubbled at the edges and flaked off, and the melt patterns of the ABS are also bad. There are no guidelines as to what power settings should be used, so maybe a 50W is just too much. Im requesting a refund, and I do not recommend these for laser-engraving.

-

Texas shopper

> 24 hourEngraved cleanly. I am a satisfied customer.

-

Texas shopper

> 24 hourEngraved cleanly. I am a satisfied customer and will order again.

-

Steven Ferguson

> 24 hourI have laser engraved and CNC engraved this product. Both options worked well. The quality is very similar to the more expensive brother and visually there is little difference. I will reorder this product. It is a good option for smaller quantities of engraving plastic.

-

Michael Rivera

> 24 hourSays its laserable, but all my research says it emits poisonous gas when lasered