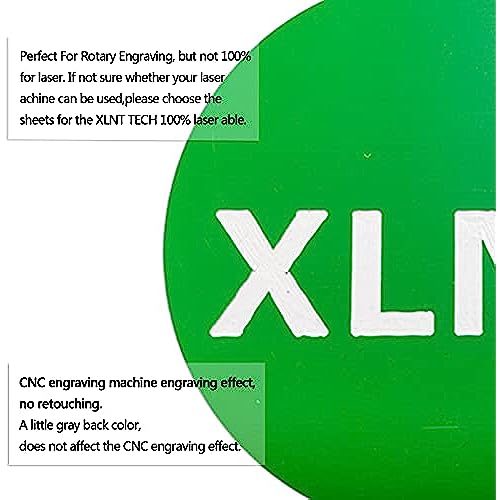

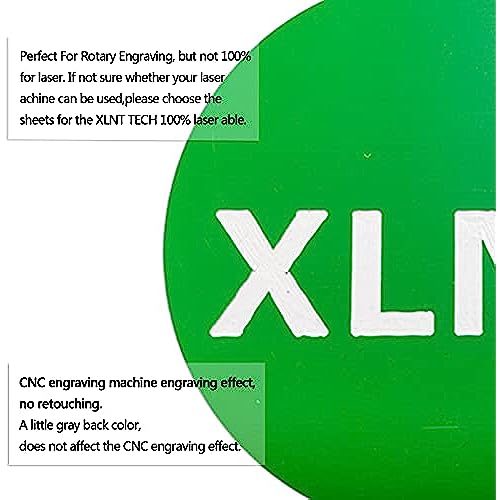

XLNT TECH Engraving Double Color Sheet (7 x 11“ x .040”, 12 Pieces & 12 Colors) for Interior Signs, Badges.

-

Robert Adams

> 3 dayAll the colors show a color layer, a white layer and then another color layer. They have a very very thin color layer, then a thick .039 white layer. I feel that the ad by the depicted display is out and out wrong. I will use them but, they are not what I ordered per ad as shown.

-

ivan

> 3 dayI got this thinking I could cnc it with my laser. turns out its actually white acrylic with a thin layer of black. so only the thin black layer got cut, and the laser did not go all the way through. useless

-

Robert Adams

> 3 dayLook at the ad it shows 3 layers. Blk,white, black. It is not. It blk/white only. Not a happy camper but I will make use of them.

-

queenidog

> 3 dayI was disappointed when I got my order. The description implies that thtere are 12 colors/12 pieces, so I was expecting one piece of each color. I didnt even have a choice of color (hence the reason I thought I was getting all colors). I got all red panels, 12 of them. Doesnt work well with laser engraver.

-

Texas shopper

> 3 dayEngraved cleanly. I am a satisfied customer and will order again.

-

Jacques St-pierre

Greater than one weekGood Selection for the price. Well packed. A bit fragile & easy to go through Did not find the proper settings for my CNC (feed rate and spindle speed) to match the material, my fault.

-

Wg

> 3 dayThe top layer is very thin and scratches easily. Handle with care. I have started spraying finished projects with clear coat to protect the appearance but that affects the finished look.

-

karin labs

> 3 dayWenn man einen Laser hat möchte man auch Schilder gravieren! Daher gehört für mich dieses Set eigentlich zur Grundausstattung

-

Rob Kilgallon

> 3 dayCO2 works best for cutting, diode works best for engraving, FYSA.

-

Joshua Landau

> 3 dayWe used this product w/ a 45w co2 laser to create signs for our facility. Works great!