XLNT TECH Engraving Double Color Sheet (7 x 11“ x .040”, 12 Pieces & 12 Colors) for Interior Signs, Badges.

-

J. Adney

> 3 dayI didn’t read the review first because I got the blue/white and had great luck. But red and white is NOT white it’s grey. And very think. Like everyone else has noted .04 thickness.

-

Texas shopper

> 3 dayEngraved cleanly. I am a satisfied customer.

-

Jason Sanderson

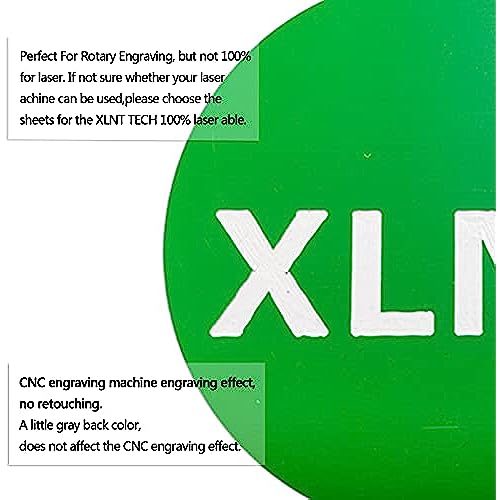

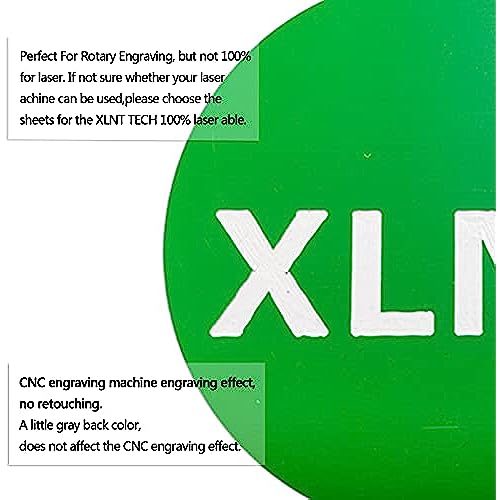

> 3 dayGreat product for CNC engraving. This product is not good for laser engraving

-

abosoxfaniam

> 3 dayProduct seemed good for making name plates, but end up subpar. When using my CNC machine to engrave nameplates, I had a bunch of issues with the top layer not cutting clean. I spent a lot of time going through with a scribe trying to get the black top layer to break free. This product is not a poured plastic topcoat, but more of a laminate on top. Pretty much a waste of my money for what I am trying to do. I was expecting clean cuts, but the top was like a layer of tape that did not want to cut clean.

-

mountaingeek

> 3 dayFirst of all, laser cutting ABS does not produce Chlorine gas like burning PCV does. So never cut PVC with a laser. That being said, burning ABS can produce hydrogen cyanide gas. How much? Difficult to say, but hydrogen cyanide gas is produced by burning many things, including cigarettes. Lasering wood also produces many toxic compounds. So no matter what you engrave or cut on a laser good ventilation and avoiding inhaling any of the fumes is necessary. Now to this particular material. Finding the right setting for your laser may take some significant trial and error. I have a Boss 1630 105W CO2 laser and ran at least 30 combinations of speed, power, air and painters tape before getting so reasonable results. The pictures are from a 6 inch wide placard I made. From 12 inches away the engraving is smooth and clean. If examined closely, you can see ridges in the cut from the laser scanning. The settings I settled on are 400 mm/sec at 35% power for the fill and 35 mm/sec at 60% power for the outline cut. Air was on and the surface was covered with painters tape to prevent smoke staining around the edges of the engraving and cut. I tried leaving the top film on instead of the painters tape but the result were not as good. The engraving was done at 300lpi. Lower lpi increased the ridges in the engraving. My only real complaint is that the white bottom layer is not very white - more of a grey.

-

Kevin

> 3 daythey were ok

-

queenidog

> 3 dayI was disappointed when I got my order. The description implies that thtere are 12 colors/12 pieces, so I was expecting one piece of each color. I didnt even have a choice of color (hence the reason I thought I was getting all colors). I got all red panels, 12 of them. Doesnt work well with laser engraver.

-

Andrew Davis

> 3 dayTop layer of color is applied unequally, resulting in an uneven color and appearance. Engraved well. Be sure to remove adhesive protective film.

-

PiperGeorge

Greater than one weekWorks good. Easy to cut. Got the variety pack and will probably buy more.

-

Texas shopper

Greater than one weekEngraved cleanly. I am a satisfied customer and will order again.