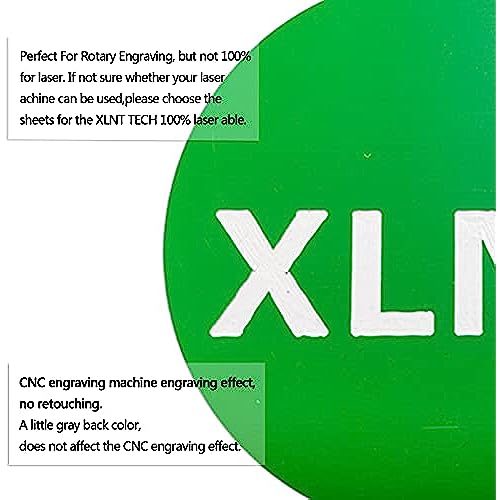

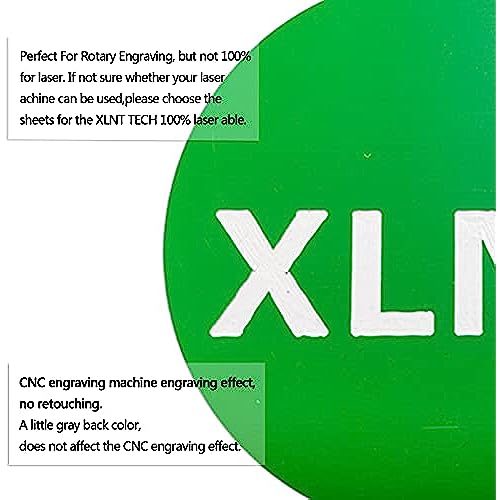

XLNT TECH Engraving Double Color Sheet (7 x 11“ x .040”, 12 Pieces & 12 Colors) for Interior Signs, Badges.

-

Prof. Annamarie Wiegand II

> 3 dayNOT WHTE!!! here is a pic of the sheet next to another makers sheet.

-

Placeholder

> 3 dayGood quality.

-

James Brewer

Greater than one weekWorks well with my 7w diode laser at 15% power. Easy to cut with a utility knife and a straight edge.

-

J. Adney

> 3 dayI didn’t read the review first because I got the blue/white and had great luck. But red and white is NOT white it’s grey. And very think. Like everyone else has noted .04 thickness.

-

Christy Mohr

> 3 dayIf you were looking for 1/8 actual acrylic this is not the product for you! This is a very thin flimsy piece of plastic. Not suitable for the glowforge. Cannot be used to create an acrylic menu or letters! Its a complete waste. Its equivalent to glitter cardstock in thickness!

-

karin labs

> 3 dayWenn man einen Laser hat möchte man auch Schilder gravieren! Daher gehört für mich dieses Set eigentlich zur Grundausstattung

-

James L. Mcintosh

> 3 dayI’m a novice laser cutter/engraver creator and this acrylic has allowed me to offer a much more professional and artistic product. Very easy to work with and an excellent variety of colors.

-

Gary Holtz

> 3 dayVery low quality. Dont waste your money

-

Robert Adams

Greater than one weekAll the colors show a color layer, a white layer and then another color layer. They have a very very thin color layer, then a thick .039 white layer. I feel that the ad by the depicted display is out and out wrong. I will use them but, they are not what I ordered per ad as shown.

-

ivan

Greater than one weekI got this thinking I could cnc it with my laser. turns out its actually white acrylic with a thin layer of black. so only the thin black layer got cut, and the laser did not go all the way through. useless