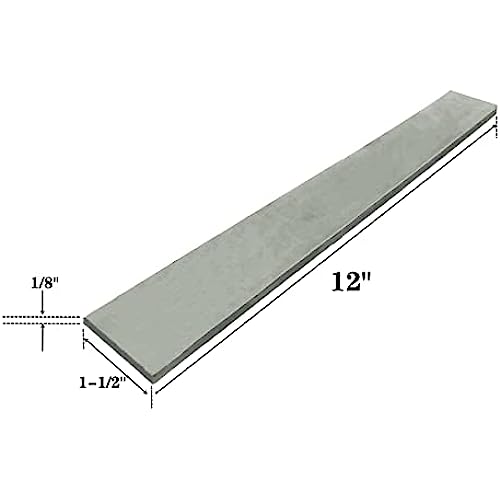

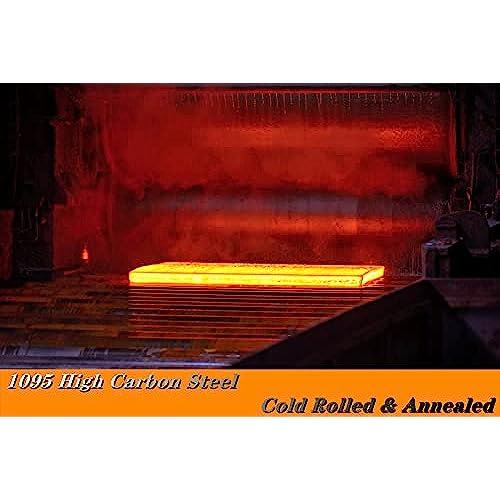

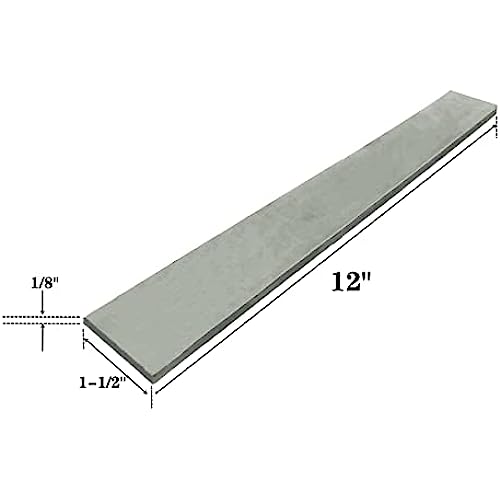

1095 Steel Flat Stock for Knife Making-Annealed High Carbon Steel,Flat Steel Bars,12x1.5x0.12,4 Pack

-

Kristen Rockwell

> 24 hourIts shiny, its hard, its magnetic, seems to be exactly what I ordered. Im no expert in making sure its exactly the type/hardness its supposed to be, but either way its steel, and the dimensions are correct. Came packaged well, no moisture, no rust. Ill be sure to update this review after working with some of the pieces, but Im sure Ill be just as pleased with it then as I am now. If you need some small pieces of flat stock for making things, this will do just fine.

-

Heather

> 24 hourMy husband is a full time bladesmith. I ordered these on a whim as he is teaching a class in the near future and was hoping to not have to use more of his high quality, expensive steel to teach damascas basics. He was excited when he saw these and was surprised that they were so clean. The measurements were also spot on which is relatively rare these days. None were bowed nor crooked. He said it was very sturdy and each blank was very clean and very strong with very minimal flexing. Hes excited to see how they handle under some heat.

-

El Jared

> 24 hourThese are good quality steel and are good for knife making or just to use as metal stock for projects. The steel is easy to work with in terms of cutting and forming. 3 of them were perfectly flat, the 4th was not. It can be bent back flat, but it tends to spring back to the curve pretty easily. I guess thats an indicator that the steel is good. Its not so good if you want to make a straight knife. Maybe I can find another use for the bent one. I like how they came packaged and were all rusty or overly oily. Perfect packaging in my opinion. Overall would recommend for knife projects where you dont want to scrounge up a piece and just want something made for that purpose.

-

Lori A.

> 24 hourNever thought I would be able to get raw steel for my husbands love of making knives, but here you can get everything. They arrived very promptly, and they were exactly what the description said they were. I am sorry that I didnt whip out my calipers to make sure that they were PERFECT...good sometimes is good enough in the forge. Looking forward to seeing what he makes with them.

-

Honey Bunz

> 24 hourThese metal blanks came well packaged they were slightly oiled which was nice, there is no rust or corrosion. This metal was as easy to work with as was described on the Internet. It is a great beginner metal. It does hold a very nice edge. Im very happy with how my knives have come out so far and I look forward to using the rest of these blanks as my craft can only improve with such great quality materials to learn from.

-

Charley

> 24 hourDecent price. Arrived with some tarnish on one bar. Two of the bars arrived with significant and visible warping. I am doing stock removal knives, so the warping is a big issue. I will have to try to correct the warping with heat treating.

-

Dave Evers

> 24 hourI’m not a knife maker, but I like keeping stock around to make scrapers and blades that can be hardened and sharpened. This is great stuff.

-

BMS

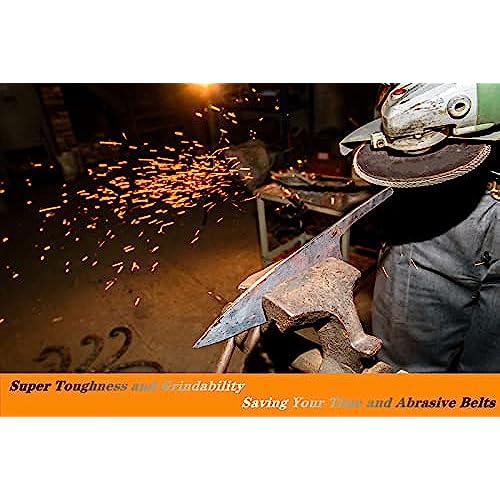

> 24 hourI’m a woodworker, leather worker and DIYer, and I’ve made knifes before with finished knife blanks where I stabilized and shaped some nice exotic hardwoods for the handles. The knifes came out good and I could customize the handle shape to my hand. I’ve read some knife making books and watched videos and it seems like you can go full on with making a knife from a wide assortment of steel components that require a forge and a lot of additional equipment or you can take smaller steps along the way. This 1095 steel provides me with those smaller steps without investing in a lot of equipment right away. I’m planning on using an angle grinder to cut out a basic chef knife shape and then using my various sanding machines to de-burr and put an edge on the blade edge. I’ll harden the edge with a torch and oil quench it (please read up on this procedure). If there are any small leftover steel pieces, I’ll try to make spokeshave blades out of them. Remember that since this is high carbon steel, you need to clean and dry your knifes after use or they’ll rust. The 1095 steel arrived in a manilla envelope. Inside the 4 1095 steel plates were wrapped in protective paper. The blanks were all coated with a little oil to prevent rusting. The blanks were clean and I couldn’t see any visible issues. I did notice that some of the bars have a very slight warp in them, probably 1/16” (see photo). For those few pieces, I’ll try to straighten them with the vise trick. I have attached photos of the measurements and they are ~1.502” wide by ~12” long and ~0.121” thick. This is the perfect next step for me in knife making, no forge or anvil required. Plus, depending on the knife I make, I can also make a sheath for it.

-

CML

> 24 hourMy son bent a piece in half with his bare hands. He tried to forge one of the pieces into a knife, but it was too thin to work with very easily.

-

Ken D

> 24 hourI wrote a review of this product some time ago, but it didnt post for some reason. Ill summarize my earlier post. Product arrived quickly and was packaged very well. Appears to be as described, though I havent done anything with them at this point. As some have noted, you wont be making large knifes with these blanks, but that isnt their intended use. I come from a line of Blacksmiths (father and grandfather). I did some hobby stuff in my youth, but went on to do other things for hobbies; mainly cars and woodworking. Due to the popular TV show, Im interested in getting back in to doing some steel work. I have my fathers manual forge blower, antique vise, tools, and anvil. Just need to work on the fire pit and i can get to work.