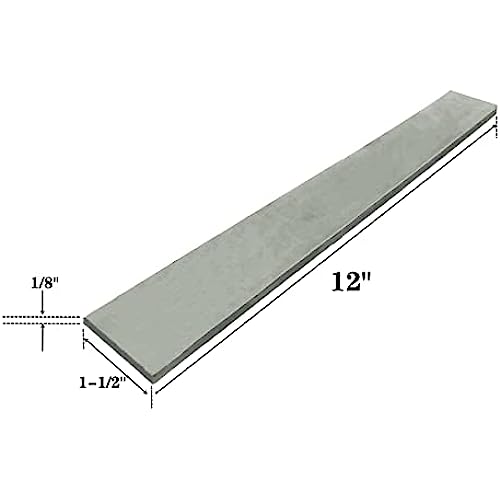

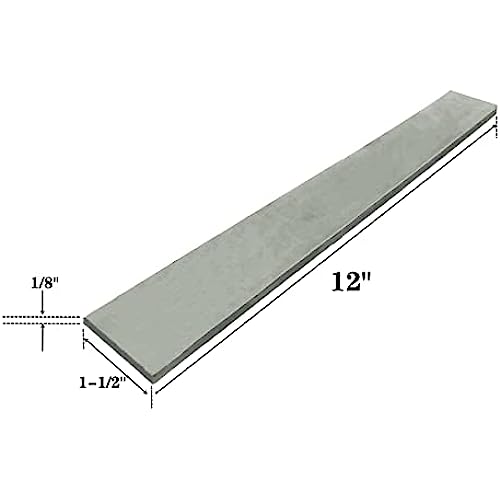

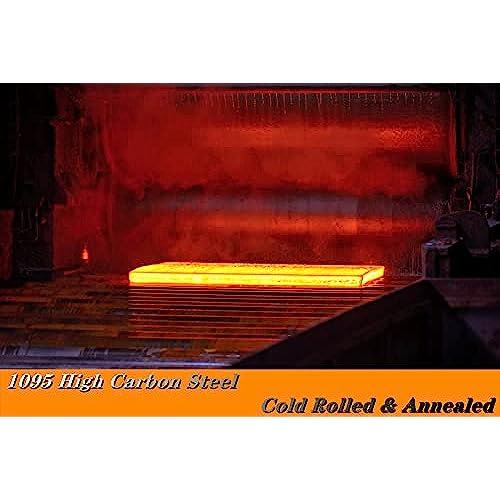

1095 Steel Flat Stock for Knife Making-Annealed High Carbon Steel,Flat Steel Bars,12x1.5x0.12,4 Pack

-

Mark Warnick

> 3 dayVery good quality and quick delivery!

-

The Prof

Greater than one weekProbably not the cheapest way to buy 1095 stock, but if you dont have a metal supply store near you, this is a convenient form factor for a knife blank or two. Cold rolled and partially annealed, this arrived at about 310 Vickers. For a stock removal forming process, thats fine-- it doesnt skate a file. There was a bit of a bow, which isnt uncommon with partial annealing of cold rolled, but might frustrate a beginner who got the most warped piece they ship and cant easily flatten it. But it was well packed in anti-corrosive and I measured it at 0.10.

-

roger seckler

> 3 dayshipping was fast,great steel for carving knivies.

-

buddha-dog

Greater than one weekThese appear to be what they claim to be. Like most folks I dont have the means to test the analysis, but it acts like 1095 as far as Ive seen. The stock is well wrapped and the bars I received are clean. I wouldnt expect to use stock like this without doing some finishing and even straightening, especially after heat-treating, so these seem to me exactly what one would expect in the way of raw stock. I would definitely do it again, but shopping on price as always for commodity material once assured I was going to get the real thing.

-

Todd

> 3 dayWhen this arrived I started thinking to myself how can I rate flat bar steel? Well as someone who welds and fabricates quite a bit of stuff around the house I can tell you this is very good quality. It arrived with a light coating of protective oil to keep it good during shipping. It was wrapping in wax paper and 3 layers of bubble wrap to protect it. When you have a company that takes the time to do their packaging like this you know it is going to be good. I mainly got this so my son could attempt to make his own knife. He has collected knives for several years and has wanted to attempt to make his own. After drawing a rough sketch that would fit the steel, he has been in the workshop most of the night working this metal. So far it is easy to work and he is making pretty good progress with it. Hopefully he will get it done soon and I can post some pictures of it for you all to see.

-

HLeveille

Greater than one weekOverall, this will work for me. Each piece is 1 foot by about 1.5 inches and a little over a 10th of inch thick. The pieces are nice, clean, and consistent and well packaged. Of the 4 pieces one is slightly curved though for me this will not prove to be a problem (I intend to get to making a tail vise mount for my work bench). For knife making, if I have a leftover piece this will make a nice Nakiri-style blade that Ill flatten slightly to end up with a 7 inch rectangular blade. For the price for 4 pieces this a good deal. For someone strictly making knives getting a curved/bowed piece might make using the full piece for a larger knife somewhat difficult. For me this wont be an issue.

-

Dr. Velva Little PhD

> 3 dayTheres not a lot to say about steel blanks, but these are as advertised: well-packaged, corrosion-free, dimensions are as promised. I lack the lab equipment to verify the carbon content, but Im confident these are going to produce excellent results.

-

BMS

> 3 dayI’m a woodworker, leather worker and DIYer, and I’ve made knifes before with finished knife blanks where I stabilized and shaped some nice exotic hardwoods for the handles. The knifes came out good and I could customize the handle shape to my hand. I’ve read some knife making books and watched videos and it seems like you can go full on with making a knife from a wide assortment of steel components that require a forge and a lot of additional equipment or you can take smaller steps along the way. This 1095 steel provides me with those smaller steps without investing in a lot of equipment right away. I’m planning on using an angle grinder to cut out a basic chef knife shape and then using my various sanding machines to de-burr and put an edge on the blade edge. I’ll harden the edge with a torch and oil quench it (please read up on this procedure). If there are any small leftover steel pieces, I’ll try to make spokeshave blades out of them. Remember that since this is high carbon steel, you need to clean and dry your knifes after use or they’ll rust. The 1095 steel arrived in a manilla envelope. Inside the 4 1095 steel plates were wrapped in protective paper. The blanks were all coated with a little oil to prevent rusting. The blanks were clean and I couldn’t see any visible issues. I did notice that some of the bars have a very slight warp in them, probably 1/16” (see photo). For those few pieces, I’ll try to straighten them with the vise trick. I have attached photos of the measurements and they are ~1.502” wide by ~12” long and ~0.121” thick. This is the perfect next step for me in knife making, no forge or anvil required. Plus, depending on the knife I make, I can also make a sheath for it.

-

Brandon

Greater than one weekThese were nice and flat with accurate dimensions. They were wrapped in oil paper and were also oiled with a smooth clean finish. Pretty good for flat stock.

-

Eve

> 3 dayThese 1095 steel plates are perfect for making knives or other edged implements. All of the bars were uniform and ready to be forged into whatever I want. Theyre very good quality.