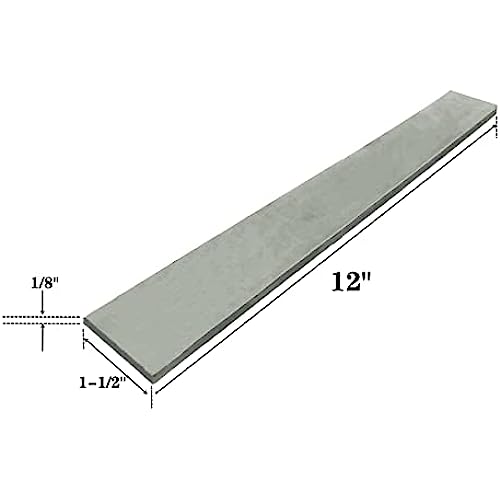

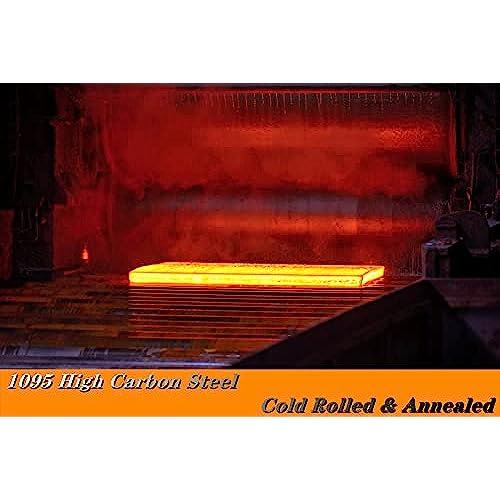

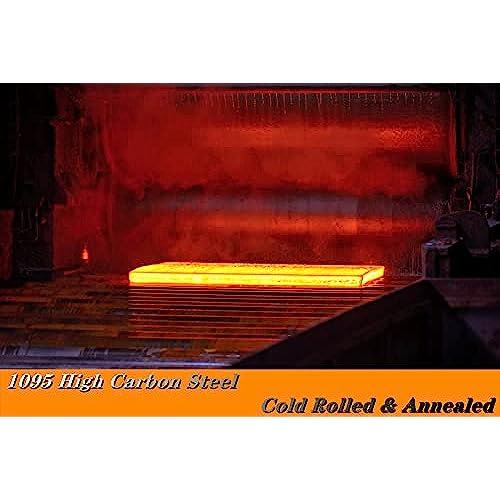

1095 Steel Flat Stock for Knife Making-Annealed High Carbon Steel,Flat Steel Bars,12x1.5x0.12,4 Pack

-

Taira Landa

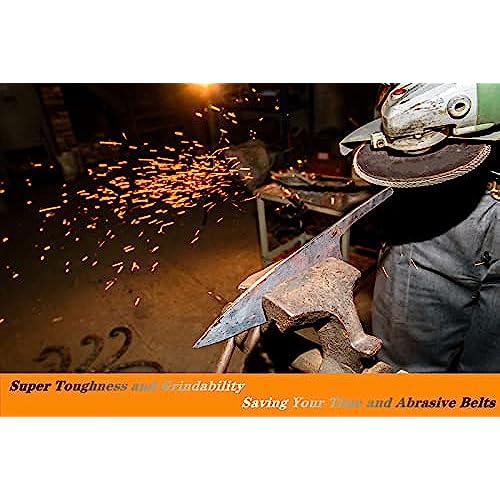

> 3 dayI like how easy it is to manipulate. Very good material for making a knife. Easy to fold and made a great knife.

-

Amanda

> 3 dayThese are good blanks. They made decent knives.

-

zarion caylon ober

> 3 dayAll my prices were bent

-

Justin Johnson

> 3 dayVery well packaged almost annoyingly so. Metal is very clean, a wipe down with some kerosene and its ready for forge welding.

-

Ken D

> 3 dayI wrote a review of this product some time ago, but it didnt post for some reason. Ill summarize my earlier post. Product arrived quickly and was packaged very well. Appears to be as described, though I havent done anything with them at this point. As some have noted, you wont be making large knifes with these blanks, but that isnt their intended use. I come from a line of Blacksmiths (father and grandfather). I did some hobby stuff in my youth, but went on to do other things for hobbies; mainly cars and woodworking. Due to the popular TV show, Im interested in getting back in to doing some steel work. I have my fathers manual forge blower, antique vise, tools, and anvil. Just need to work on the fire pit and i can get to work.

-

isaac

> 3 dayThe steak was high quality and was with in the given specifications.

-

BT

> 3 dayThese Steel Bars came wrapped in anti rust paper and then in a tightly packed bubble wrap mailer. The steel bars had no rust and only very minor surface scratches. All three of them are the same size and they are straight with no bow or twist. I did a grind test on them and they do seem to be high carbon like they say they are. Overall, I am quite pleased with how they were packaged and the general quality of the steel.

-

roger slone

> 3 dayFor the price, approximately 5.50 a piece, its a good deal. Should make some good blades when hardened. It looks like it was stamped or sheared to size and I believe that gave the metal a slight bow. That will need to be worked out before hardening. Other than that, whats not to like, Good steel.

-

Seekir

> 3 dayMy son and his uncle have a hobby of knife making with a home made forge. They stated that this was hard steel that was able to be worked into a knife.

-

Joel P.

> 3 dayThese steel blanks come shiny (not polished, but free of scale) and oiled. They were exactly 1.50 wide and 1.20 thick (so not quite the 1.25 of 1/8). Mine all had a slight bow to them over the 12 length, but its not anything I wouldnt be able to correct for. All-in-all, a decent product for the money.