Brush Research FLEX-HONE Cylinder Hone, GB Series, Silicon Carbide Abrasive, 4-1/8 (105 mm) Diameter, 240 Grit Size

-

Kelly D

> 24 hourChucked it up in my drill, steady speed & motion, perfect results. Happy camper.

-

Alan

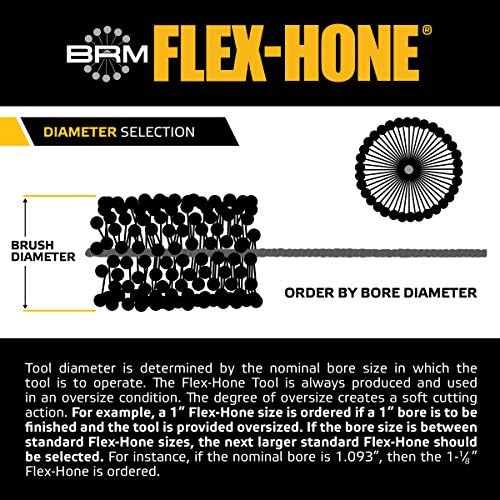

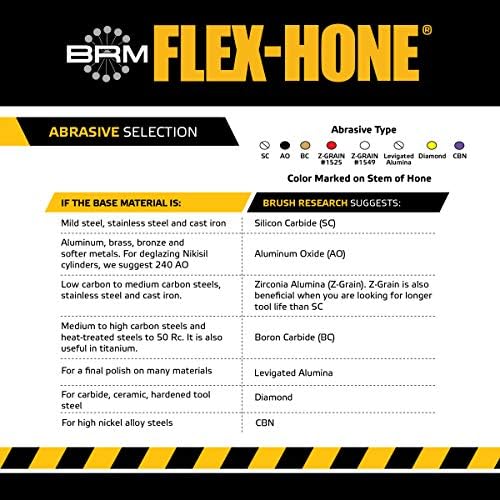

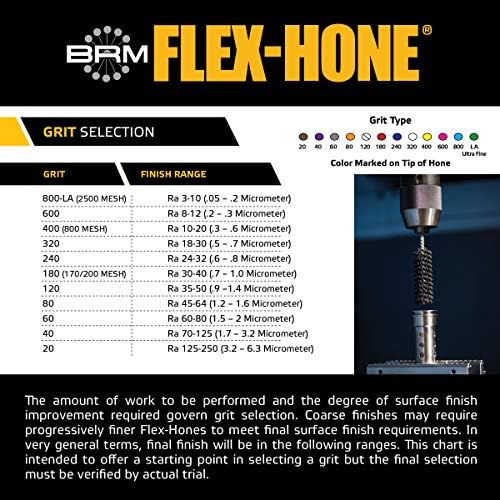

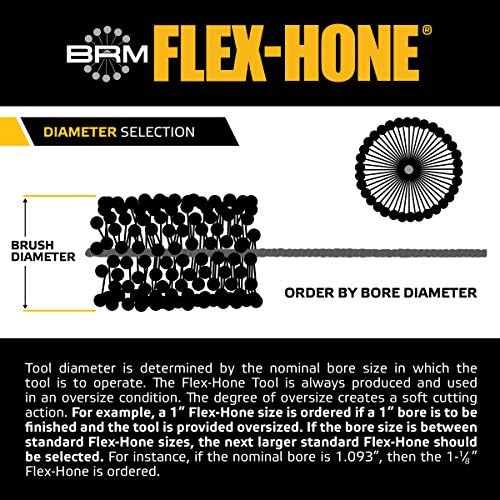

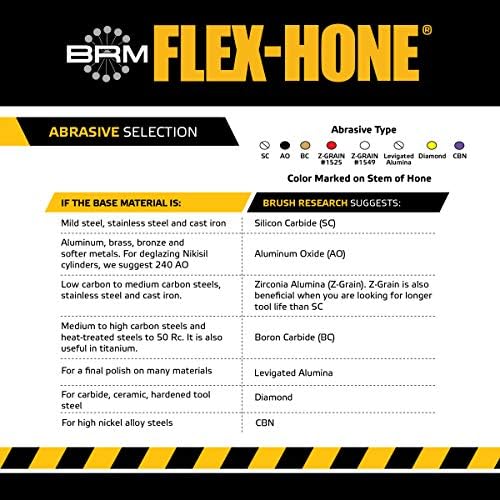

> 24 hourThis seems to be a well made tool. The abrasive tip is connected to the metal center with plastic leaders but they seem to be sturdy enough to handle the work. If you are reading this you know what it is for and it seems to fit the bill quite well. Keep in mind when purchasing that you will want to make sure you get the size and grit needed for your application.

-

BiGG Willi

> 24 hourVery easy to use with a good drill.

-

J. Shade

> 24 hourFast, easy to use. I lubricated with transmission fluid. Took glaze off fast and left nice crosshatch. You must move quickly up and down. Lubricate hone between each cylinder.

-

Howard Brown

> 24 hourGot the hone oil a must to keep it wet. My option.

-

Angie

> 24 hourStock engine refresh 4.0in bore. This thing worked great. Tip: Get a buddy and make them keep it flooded with lube while you stroke it;) Use wd40 or whatever is cheap. Youll use most of a can. Then wash that engine with soapy water and a brush, or just pressure wash it. Its going have lots of fine metal particles everywhere from the hone process.

-

John O.

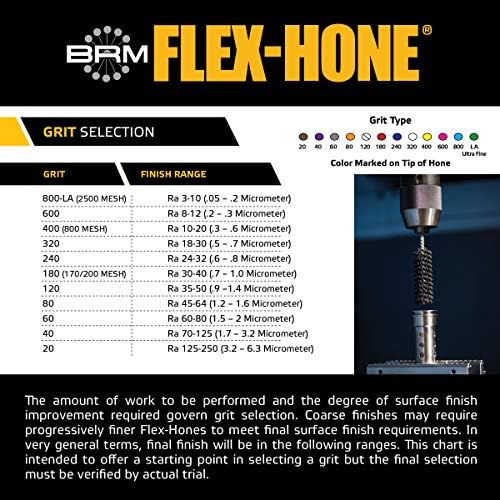

> 24 hourThese guys make the best hones I have used over 30 years. If you use this hone correctly you can bore a cylinder out 10,000ths top to bottom evenly for 10 over pistons and rings. I do this in a variable speed drill but it can be done in a drill press too. You must check all points in the cylinder often, cleaning as you go. Use a coarse hone to get most of it then change to a hone grit specified by your piston and ring manufacturers. Clean the cylinder and oil it testing with the piston for clearance. Use your micrometer til you reach spec so you dont get your piston stuck in the cylinder. Dont Rush!! Watch a cylinder honing machine on you-tube to understand the motion you must use to keep the honing even. Always use a quality honing oil.

-

ANDY

> 24 hourShould be in all tool boxes

-

mycreativename

> 24 hourWorked fantastic to hone a 4.7 HO from an 02 Grand Cherokee. I used 5w-30 as the lubricating oil (it says on both their website and the instructions on the box that you can either use their cutting oil or just a normal 5w-30 oil), put a couple sheets of cardboard below the engine block and went to it. Watch a few videos on how to do it and the rhythm to use to achieve your correct cross hatching pattern and youll be good to go. It took me two cylinders to get it right where I wanted it and then I was golden. Make sure when doing it, you use the hone as little as you need to so you dont overdo it (Not really sure if you could, but thats the general rule Ive always heard with these and figure it cant hurt to go by it).

-

Mark Bryant

> 24 hourRebuilt a Jeep Grand Cherokee 4.0L (straight six) without removing the engine from the vehicle, and the Flex-Hone worked great for me. Did a lot of homework before using, to understand exactly what the procedure was and that I had the necessary drill, clearance, fluids, posture, RPM, and honing technique. I had to mod the hone to weld a hex bit to the shaft (making it as short as possible from drill back to hone-front for the mounted engine), but managed to get the job done. I would not have been able to use any other traditional honing tool in the space, and it was very forgiving for the angles I was working with.