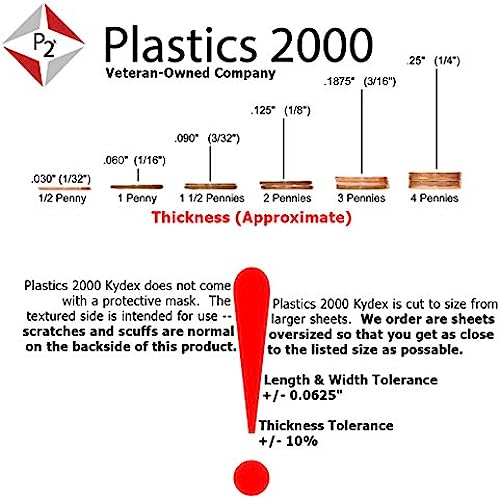

Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

Chad Bahringer

> 24 hourPerfect size for my holsters n sheaths

-

Parker Geurin

> 24 hourMade a knife sheath and an axe cover Andy still have an entire sheet left. Works great!

-

Tyler K. Smith

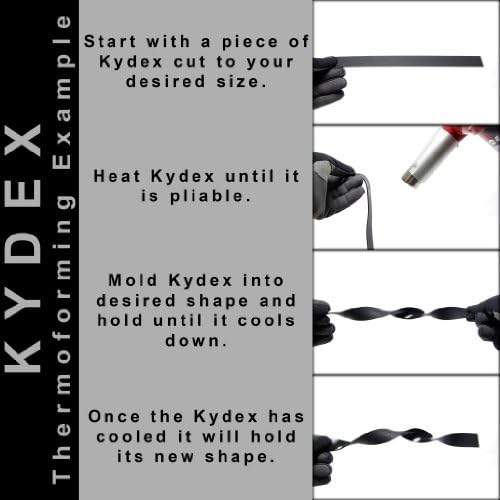

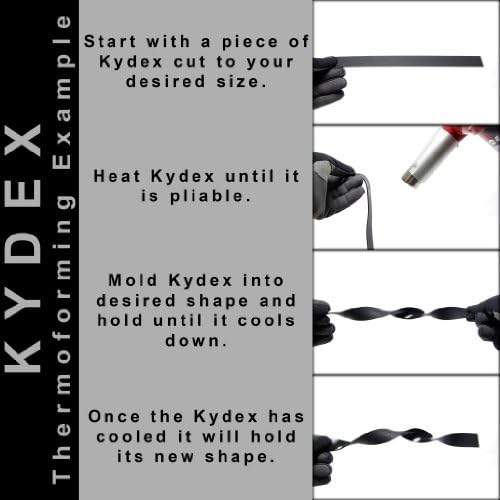

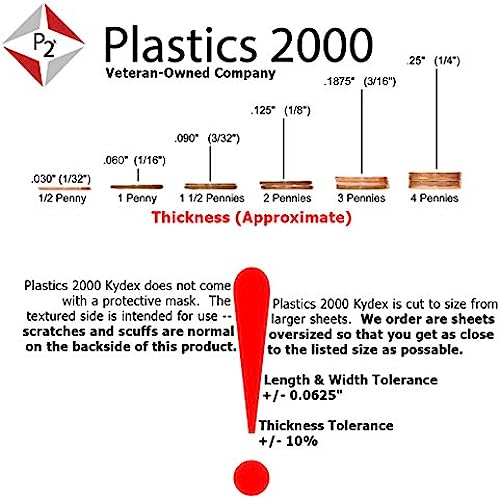

> 24 hourI purchased this to mold a tuckable belt clip for my kydex holsters and I have not been disappointed yet. It appears to be very durable but it was still easy to manipulate after being heated with a heat gun. I would have liked to have purchased a size thicker for a belt clip, but this would be great for making an actual holster out of.

-

sidehill

> 24 hourI made sheaths for a couple of good chef/filllet knives so I can store them in a drawer with other utensils. The material was easy to work with and made nice sheaths.

-

Jamie

> 24 hourGreat product worked great for the use I bought it for.

-

Len Hill

> 24 hourGood stuff

-

Teagan

> 24 hourIt was thick enough to be sturdy and strong but still very easy to cut. Perfect for DIY and cosplay projects

-

kris

> 24 hourWorks just like Kydex oh wait it is Kydex

-

Sgt Apone

> 24 hourRough and satin on one side, not as rough and a little glossier on the back. Score it a few times and break it off. Very sturdy for the thickness. Worked perfect for the project I bought it for.

-

Jay

> 24 hourNo complaints but it think the price is a bit steep, $5 for a piece of plastic seems a little ridiculous