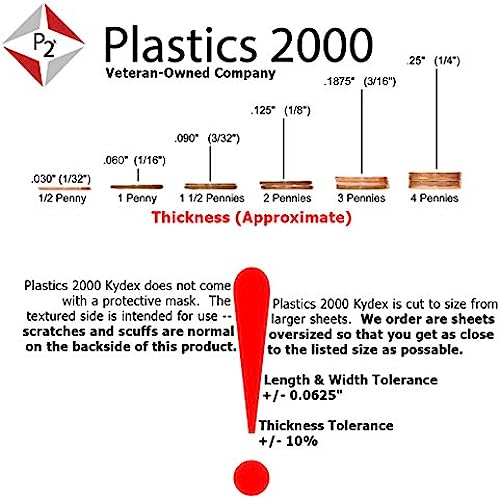

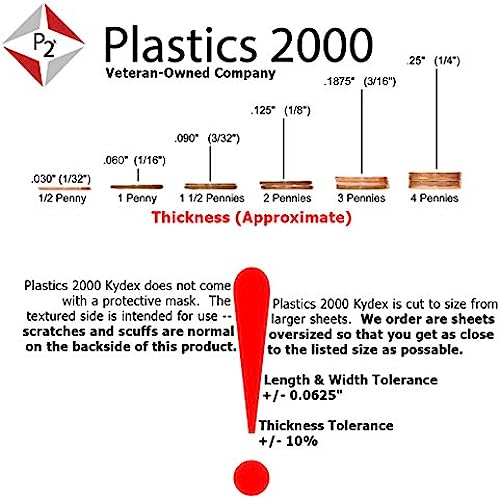

Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

Randy

09-06-2025Fast and easy.Will business again

-

michael

Greater than one weekPerfect!!!!

-

Gabriel D.

> 3 dayShapes well and is solid.

-

kris

Greater than one weekWorks just like Kydex oh wait it is Kydex

-

Skipster

> 3 dayCut to size as ordered and received in excellent condition with out any scratches scrapes or dings. My only negative comment would be that they were not as think as I had expected. I bought the .08 thickness which was the thickest available but it isnt as thick as my holsters or as expected. Still did what I needed it to and was a fair price no doubt and Ill likely but again. A all around a solid product at a fair price.

-

Frank J. Rodriguez

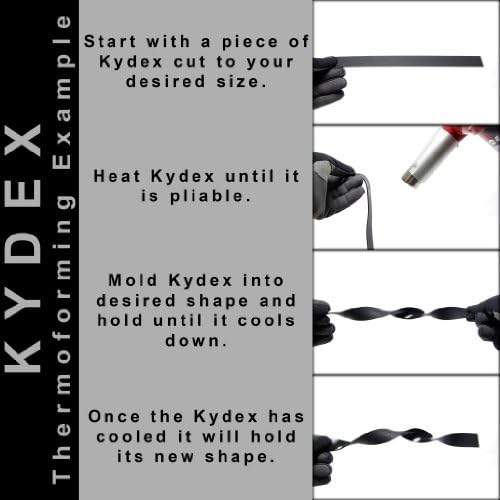

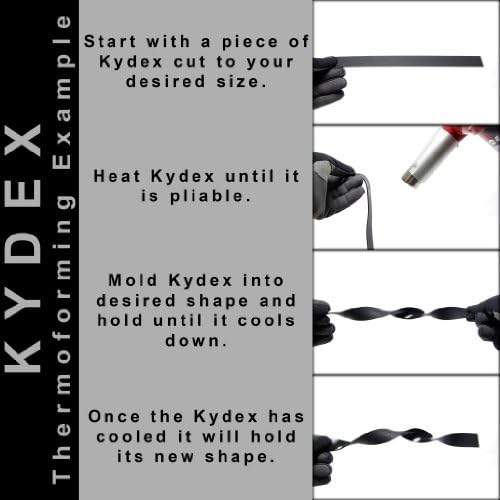

> 3 dayCan’t tell u how I liked the product cuz I can’t use it, cuz it did not come with instructions!!

-

Mark

> 3 dayI made a minimalist holster for my carry firearm. The product is easy to shape and very strong.

-

Fishook

> 3 dayGreat for models

-

ladymad

> 3 dayknife case

-

Mary & Vinnie

> 3 dayNot the best price but it came fast and it came as described.