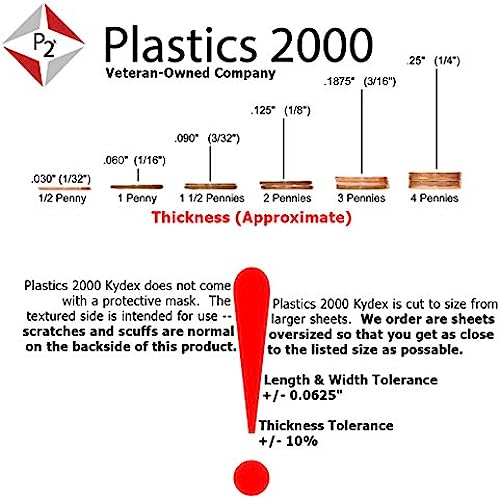

Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

Lana

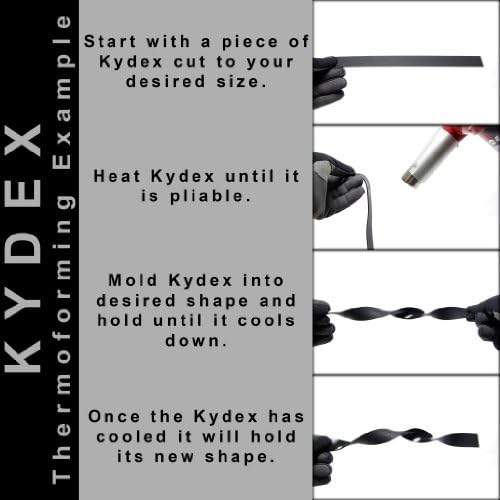

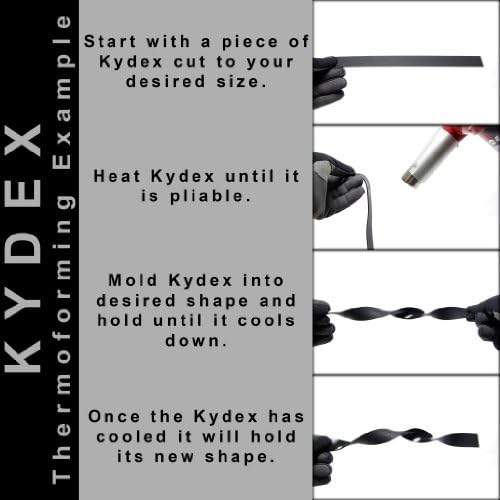

> 3 dayI used this for a couple of holsters. It works great. You can rewarm it with a heat gun to make adjustments.

-

Unbelievable

> 3 dayOne of the best kydex sheetings. Used this exact kydex befor and works wonders

-

Edward Scott Allen

08-06-2025About this product to make combination plates for vintage Kustom Amplifiers I found that it was best to cut this Kydex on my tablesaw because it gave a clean edge. I would not recommend using a bandsaw or a jigsaw For cutting into pieces, or knife blades, the jig saw and the band saw blades possibly were not the proper choice for the job.

-

Bill West

Greater than one weekwith a simple heat gun the material quickly become pliable and easy to shape. I plan many more projects with Kydex.

-

Brad Swasey

Greater than one weekIts easy to work with and feels quite durable

-

Connor P

> 3 dayGood luck trying to cut this down to the exact size you need for your project.

-

Kev

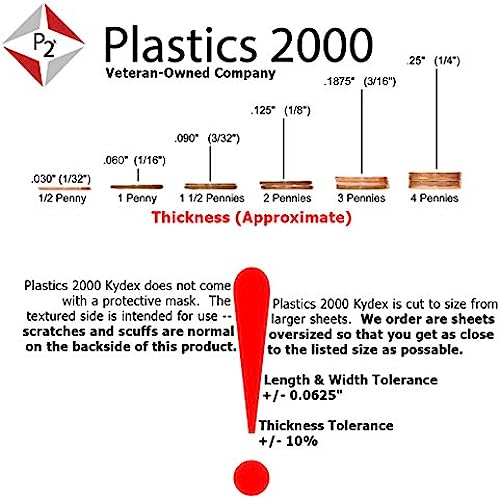

> 3 dayFor my first time working with Kydex I would say this is a win. Using a heat gun on low I was easily able to form a small section after scoring it with a utility knife and snapping off what I needed. I did a holster strut repair which looks as good as the original and seems more sturdy using the .080, the original was .060.

-

Gcarroll73

> 3 dayPerfect for my sheath making.

-

Cameron

> 3 dayThis stuffs pretty neat. It was my first time using kydex. It was very forgiving. I tried it at 200 and 300 degrees Fahrenheit. Messed up several times and re-heated the sheets of kydex. Seemed to come out fine!

-

Jeremy

Greater than one weekKydex is great and quality is good. One note for buyers: the sheets I received are now 8x12, they are 7 7/8 x 11 7/8. If you need a 12” sheet, this will not work.