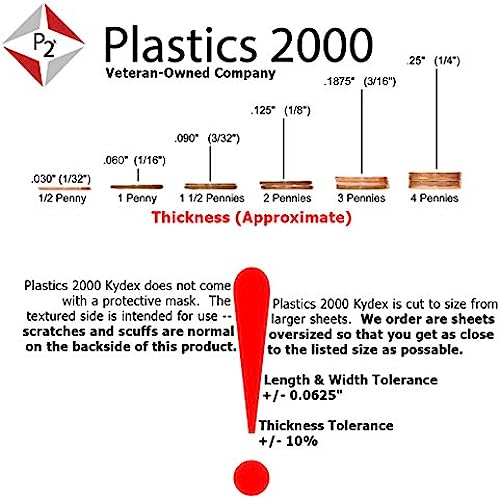

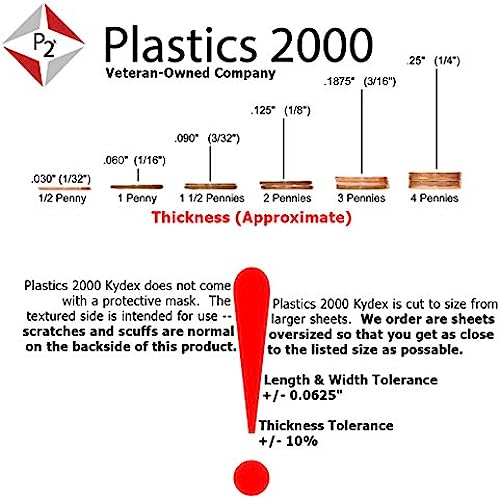

Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

chris m. gehring

> 3 dayUsed to make a light bearing holster, worked perfectly. Thanks

-

Fishook

> 3 dayGreat for models

-

Sgt Apone

> 3 dayRough and satin on one side, not as rough and a little glossier on the back. Score it a few times and break it off. Very sturdy for the thickness. Worked perfect for the project I bought it for.

-

Kindle Customer

> 3 dayGreat price great product.

-

A. Phibbs

> 3 dayExactly what I was expecting, and stamped made in USA right on it.

-

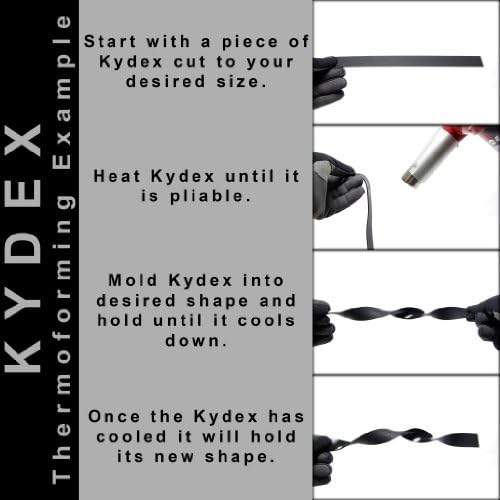

Cameron

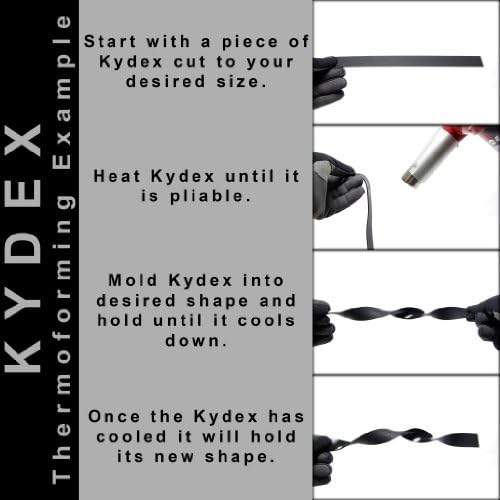

> 3 dayThis stuffs pretty neat. It was my first time using kydex. It was very forgiving. I tried it at 200 and 300 degrees Fahrenheit. Messed up several times and re-heated the sheets of kydex. Seemed to come out fine!

-

Ronald Y.

> 3 dayI used this for my 2003 Zuma 50. In the process of modifying the frame and I had to cut out a portion of the storage compartment. A buddy told me about this stuff so I gave it a shot. From what I understand, using a heatgun to mold this can be pretty time consuming. Luckily, I have a powdercoating oven. Just cranked it to 350F and waited for the material to reach 290F to 300F (about 15 min). Laid it down in the scooter tub and it only took about a minute to cool down. I used some 5-minute epoxy to glue it to the tub and that was that! Easy peasy. Love this stuff.

-

EngineerInventorProgrammer

> 3 dayI used a heat gun to make several sheaths and a holster. Add a few Chicago screws and it looks store bought.

-

bryan

> 3 dayI heated it up in the oven and shaped it as needed. Very easy to work with

-

Lana

> 3 dayI used this for a couple of holsters. It works great. You can rewarm it with a heat gun to make adjustments.