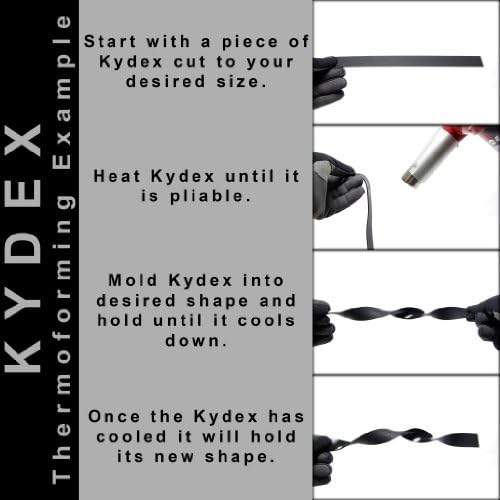

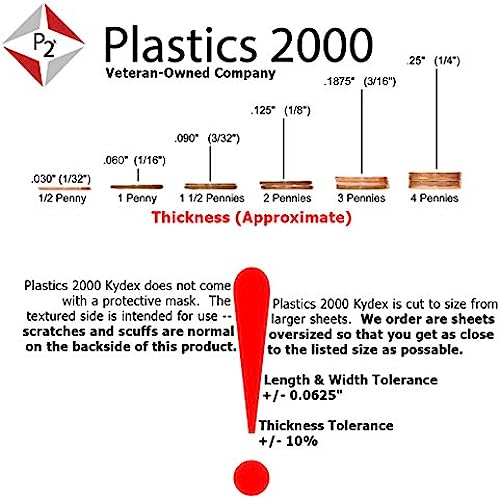

Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

Mark

> 3 dayI made a minimalist holster for my carry firearm. The product is easy to shape and very strong.

-

Teagan

Greater than one weekIt was thick enough to be sturdy and strong but still very easy to cut. Perfect for DIY and cosplay projects

-

CILIO J PACHECO

> 3 dayUsed this to make cheek risers for my rifles. Worked perfectly.

-

samuel

> 3 dayThat said it works well.

-

ladymad

> 3 dayknife case

-

Sean P

> 3 dayLoved it! Worked out perfectly

-

Mike K.

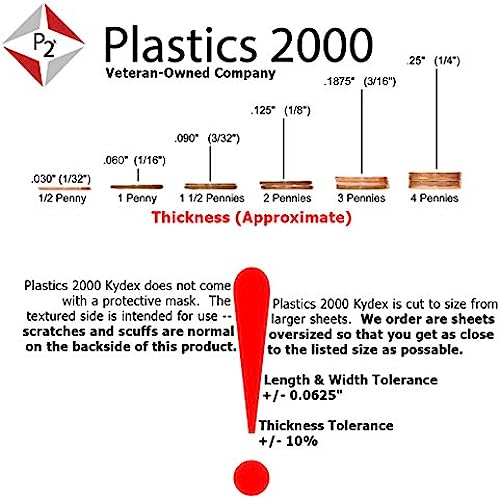

> 3 dayDon’t have it yet but I LOVE your thickness picture using pennies. VERY VERY Smart!!!!

-

charles

> 3 dayrecommended

-

Parker Geurin

> 3 dayMade a knife sheath and an axe cover Andy still have an entire sheet left. Works great!

-

michael

Greater than one weekPerfect!!!!