Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

Chad Bahringer

> 3 dayPerfect size for my holsters n sheaths

-

ladymad

> 3 dayknife case

-

Jay

> 3 dayNo complaints but it think the price is a bit steep, $5 for a piece of plastic seems a little ridiculous

-

Kev

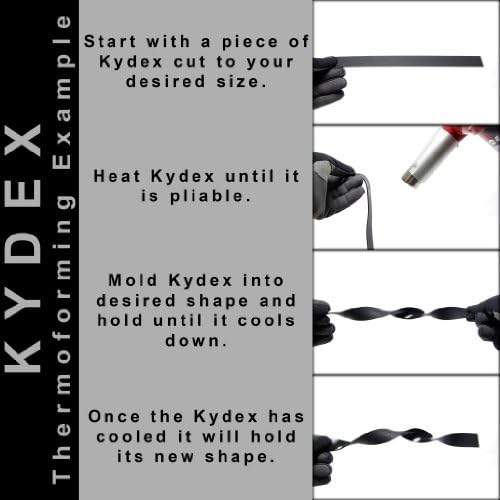

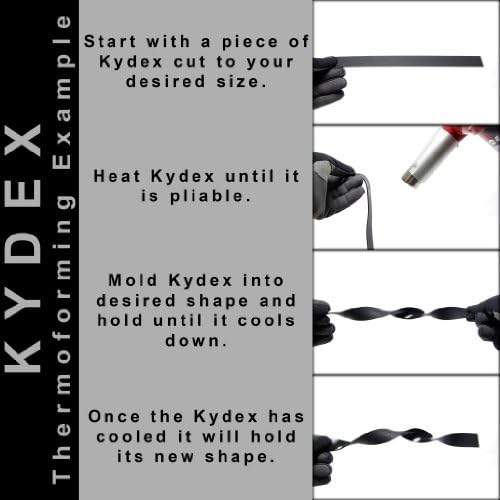

> 3 dayFor my first time working with Kydex I would say this is a win. Using a heat gun on low I was easily able to form a small section after scoring it with a utility knife and snapping off what I needed. I did a holster strut repair which looks as good as the original and seems more sturdy using the .080, the original was .060.

-

Mike K.

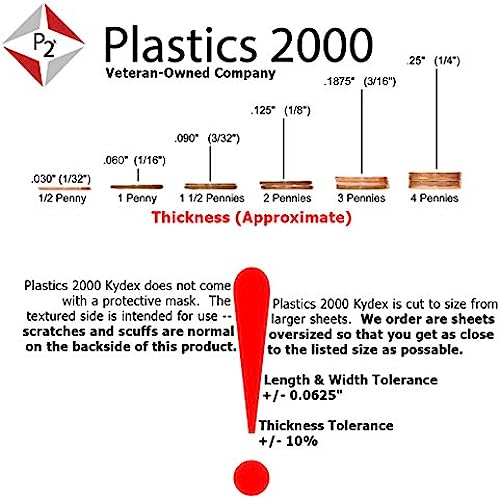

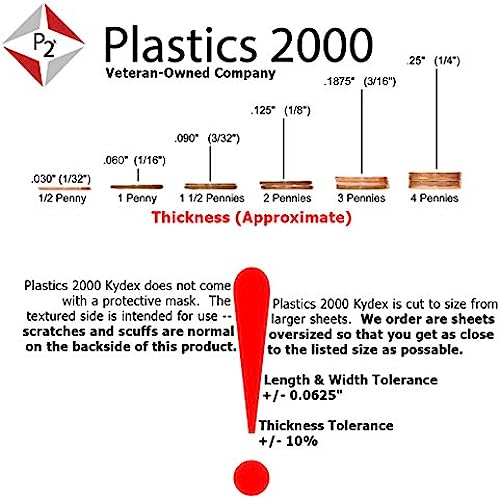

Greater than one weekDon’t have it yet but I LOVE your thickness picture using pennies. VERY VERY Smart!!!!

-

Jstanker

> 3 dayJust what I was looking for to make an adjustable cheek rest

-

Gabriel D.

> 3 dayShapes well and is solid.

-

Dan Bradley

Greater than one weekFound heating in the oven much better than a hair dryer, lol. molds very well and was easy to trim. nice product.

-

Parker Geurin

> 3 dayMade a knife sheath and an axe cover Andy still have an entire sheet left. Works great!

-

Stephen

> 3 dayThe real deal. Made in the USA