Plastics 2000 - KYDEX Sheet - 0.080 Thick, Black, 8 x 12, 2 Pack

-

AJ Sevag

> 24 hourGood quality kydex.

-

Kev

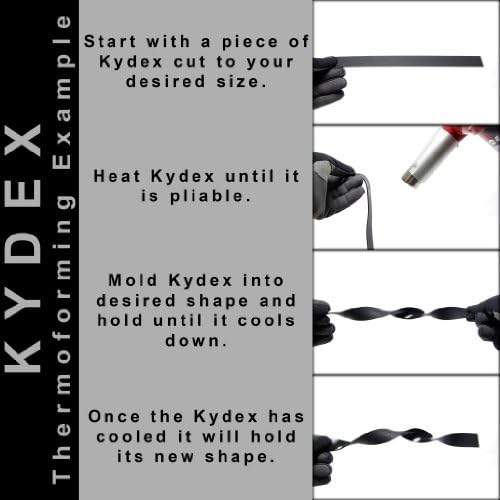

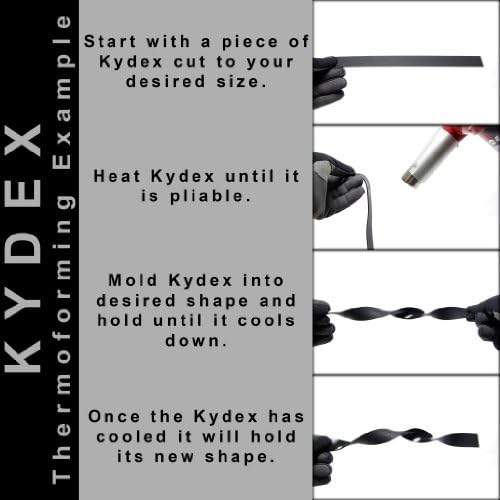

> 24 hourFor my first time working with Kydex I would say this is a win. Using a heat gun on low I was easily able to form a small section after scoring it with a utility knife and snapping off what I needed. I did a holster strut repair which looks as good as the original and seems more sturdy using the .080, the original was .060.

-

Keene

> 24 hourIf you ever felt ripped off over a kydex sheath buy some and give it a go. Easy to work with and a good thickness.

-

Stan

> 24 hourAs advertised. Workable material as it should be. Veteran owned company.

-

Mike K.

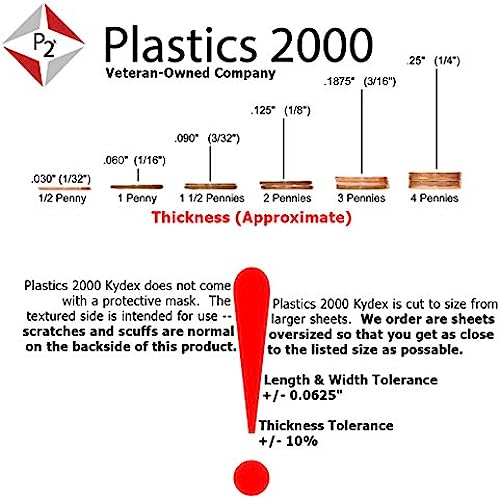

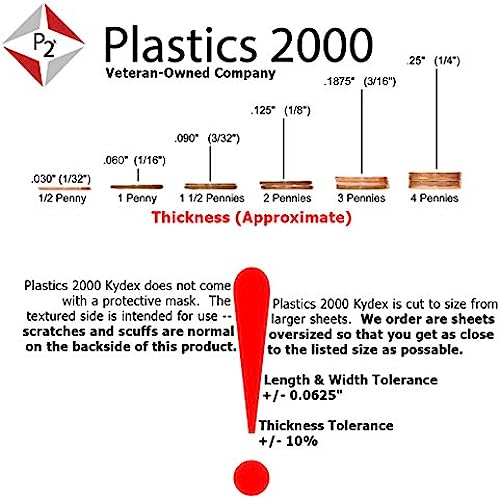

> 24 hourDon’t have it yet but I LOVE your thickness picture using pennies. VERY VERY Smart!!!!

-

CK Custom Knives

> 24 hourPerfect for my knife sheaths

-

Stephen

> 24 hourThe real deal. Made in the USA

-

Frank J. Rodriguez

> 24 hourCan’t tell u how I liked the product cuz I can’t use it, cuz it did not come with instructions!!

-

Belle Crist

> 24 hourGreat

-

Skipster

> 24 hourCut to size as ordered and received in excellent condition with out any scratches scrapes or dings. My only negative comment would be that they were not as think as I had expected. I bought the .08 thickness which was the thickest available but it isnt as thick as my holsters or as expected. Still did what I needed it to and was a fair price no doubt and Ill likely but again. A all around a solid product at a fair price.