Brush Research GBD40024 FLEX-HONE, 4 (101mm) Diameter, 240 Grit, Silicon Carbide Abrasive (Pack of 1)

-

Thomas Hughes

> 24 hour....looks great, arrived fast!

-

Michael Beach

> 24 hourDoes a beautiful job as advertised. No complaints on performance or price.

-

jon

> 24 hournew tech.?

-

SECRET SHOPPER

> 24 hourWorked Great !

-

Bob F.

> 24 hourGreat for refreshing any EJ25, they have a 99.5MM or 3.91 inch bore for the 4 inch hone works great for them. I have done 2 of them now, put the drill on low speed and squirt oil on them as you go will give good results.

-

bud

> 24 hourliked the hone, but yikes!, the price!

-

Richard bendel

> 24 hourthese flex zones will give you the best results ever

-

Jon Whitehead

> 24 hourIt has a large surface area for big or small jobs. Great looking quality. Balls did not easily chip in shipping as some hones do.

-

tkirk

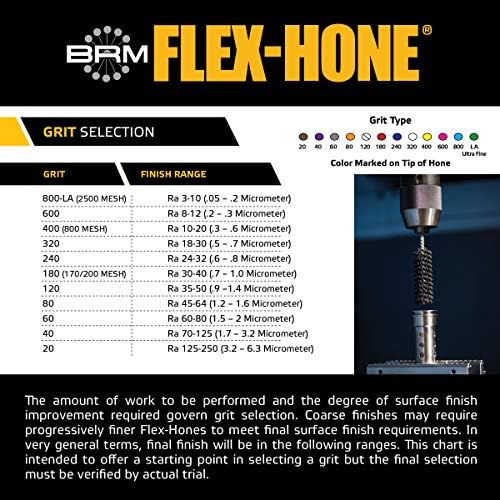

> 24 hourI used these per ring manufacturer recommendation for grit. Worked perfect. Easy to use.

-

Ab6

> 24 hourSpec was crosshatch 30 to 45 degrees. Profiled the wet sleeves first, they were all in spec, so went to town. Low speed drill, brisk in out action achieves great results. Lubricate the hone before every use. Go a little past the return direction so you reduce the low angles at the end of the stroke.