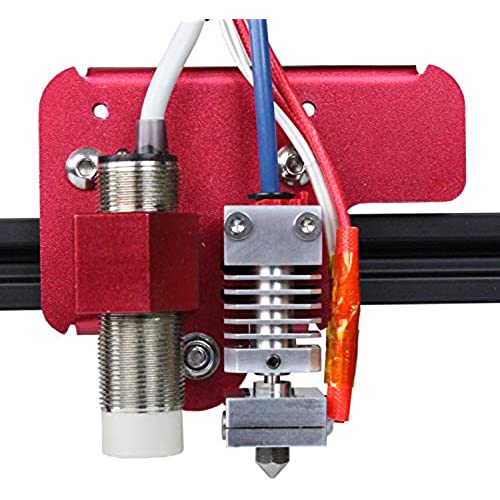

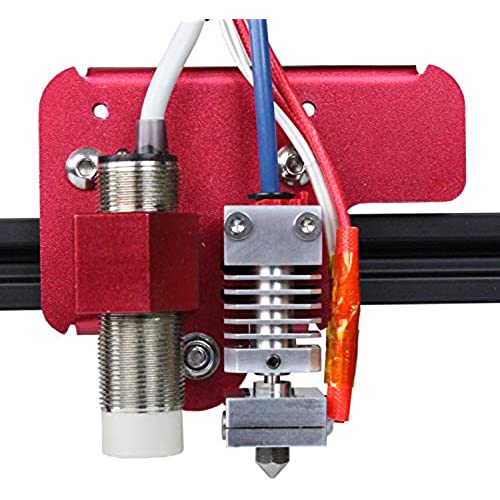

Micro-Swiss All Metal Hotend Kit for Creality CR-10s PRO/CR-10 Max/Ender 3 V2 Neo

-

Steven J. Headlee

> 24 hourYes sir. Thats right. Do it, you wont regret it. Best upgrade Ive done so far. And Ive done a bunch. And yes it fits the Ender 3 Pro.

-

Alex Hodge

> 24 hourNot much to like here. The first kit was complete and got to the point of hot tightening the nozzle when the nozzle sheered off in the heat block with the torque driver set to 30 inch pounds as specified. Replacement kit, well I have no idea how the nozzle will fair since its missing the two screws that should be installed in the heater block to hold the heater in place. No way to tighten around the heater. Im going to dig through my tiny screw collection before returning it because I dont want the hassle but Im disappointed. Ive used Micro Swiss on printers in the past and they were great. Its too bad theyve gone so far downhill over the last few years.

-

Dave

> 24 hourThis is a great drop in replacement. No problems so far with it.

-

Phantom

> 24 hourCould not install nozzle it came with fully even after heating to 200 celcius. Could be a random bad one?

-

Austin bob

> 24 hourNice extruder needs so modifications to design to keep the grub screw from stripping. Need to tap the right or left side for a longer grub screw the same size to give more threads to bite on too, if you remove the grub screw a few time like 10 over the years the threads get wreckt. Also a longer grub screw to fully take advantage of the very small amount of threads would have also helped the problem, poor engineering. Excellent quality overall. Wouldnt suggest the price point till they redesign the extruder. That is the only problem Ive ever had with it.

-

Brian

> 24 hourI wish I could give this hot-end a better review. It is very well made to say the least. That is why I gave it three stars. The hardware they supply is a little subpar. One of the screws that holds the hot end to the printer literally had no way to use it. It was perfectly round inside with no way for the allen key to grab it. I dont blame Microswiss for this as I doubt they make the hardware. I actually installed this hot end right after I made my first print with the original CR hotend. I followed the instructions to the letter. Used a torque wrench and followed some of the tips left in the comment sections. But I kept getting brittle prints and stringing issues. I tried various temps, and finally decided I wanted to try my original hotend once again. I had noticed on a couple prints that the tip would get a little goopy so to speak. So I would clean it off. It wasnt until I pulled the fan cover off to swap it out that I discovered there is a leak. and the whole hotend was covered in PLA. The heating element has literally welded itself inside the hotend. So I am not sure where it all went wrong... But it went wrong :p Ordered an original CR10s Pro hotend kit. This is mostly a hobby, and I doubt I will ever be printing exotic materials. If I do.... I shall revisit this hotend.

-

bmwboyee

> 24 hourI dont have much to add about this product other than it does exactly what it says it will do. I needed this hotend to print higher temp material and it does a great job. The construction of the throat is much more robust and does not rely on the PTFE tube. This reduces the risk of clogging. Installation was an exact replacement and I had no problems at all on my Ender 5. It was plug and play. I did end up buying the microswiss hardened nozzle because I wanted to print carbon fiber. It has held up very well also and would suggest adding to your order. The value of the hotend I would say is in the medium range. It does perform well but being sometimes 1/4 of the price of the printer....just doesnt score well on overall value. I do support that it is made in the USA so Im willing to take that into consideration. I would still highly suggest this hotend if you would like reliable hotend for every print.

-

Alexis Smith

> 24 hourI have never had so much confidence in my CR10 MAX until I put this on. Biggest difference other than quality is that you can use normal threaded nozzles! Great product. I’m never scared to print even really large things.

-

4ric

> 24 hourIve tried several hot ends on my Ender 3 and my Ender 5. Ive had trouble with some of the V6 setups, and decided to give microswiss a try. Ive ended up installing it on both machines. It is a super easy retrofit, as it mounts on the stock creality gantry with no modifications. The spacing on the second one that I ordered seemed to be slightly different than the first, as my nozzle would hit the table before my BLTouch homed out. I printed a spacer for the BLTouch to move it further down, and everything has been great since. I havent had a clog from retraction yet, which was my main gripe with the V6 hot ends. Its also blown through a spool of Polycarbonate filament at 260 degrees without a problem, using the stock heating element and thermistor from creality. Seriously, give this thing a try if you need to print higher temperatures!

-

Yoshisuke Kuramoto

> 24 hourI bought two of this kits. I bought the first one 6 months ago. Bcause the quality of the Chinese all-metal hot end I was using until then was poor. But last month, I broke the titanium throat when I tried to remove it from the heatsink to correct the angle of the hot end block. The cause was that the titanium throat was stuck to the aluminum heat sink. Heat resistant silicone paste should have been applied to the titanium throat and heat sink attachments. Amazon didnt sell only titanium throats and heatsinks, so I bought the second one as well. After that, the screw at the nozzle mounting part of the heat end block broke. The heat end block wasnt wasted. I use various filaments such as Nylon, Carbon filled Nylon, PC, Carbon filled PC, TPU, and TPE according to the purpose of the model. For this reason I change the nozzles frequently. I intended to be careful not to overtighten the nozzle, but the screw on the heat end block broken. I think this kit has very good performance, but this kit needs to be handled with great care.