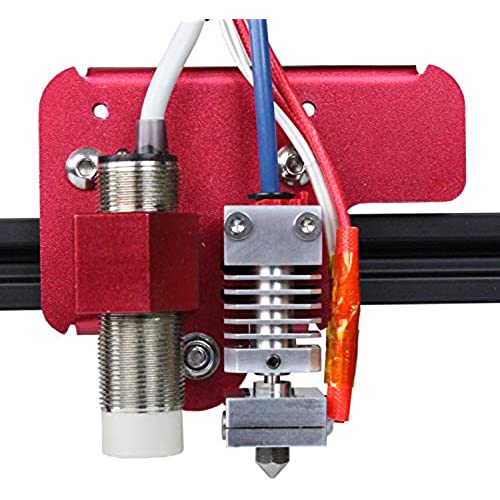

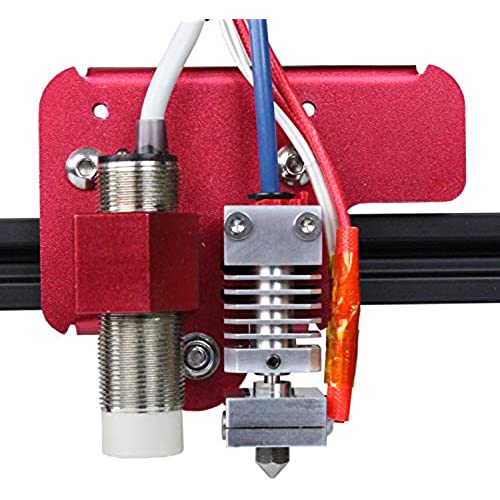

Micro-Swiss All Metal Hotend Kit for Creality CR-10s PRO/CR-10 Max/Ender 3 V2 Neo

-

Tyler A.

> 3 dayMissing the neck to use it...I took the jump on this but Im returning it and wont be coming back

-

Steven J. Headlee

> 3 dayYes sir. Thats right. Do it, you wont regret it. Best upgrade Ive done so far. And Ive done a bunch. And yes it fits the Ender 3 Pro.

-

C. Lane

> 3 dayThis is a direct replacement for the factory hot end. Remove the old one, trim the bowdin tube square, pre heat the hot end before tightening the nozzle. Then print! This works really well.

-

Johnny M.

> 3 dayThis started out strong. Good prints. But now, it has died. Well, inside the part that screws to the heater block with a tiny allen screw eventually died. And no matter what I do, it just doesnt print

-

Jolie Pagac

> 3 dayI recommend look a better options. This has been a waste of money and time. I continue to get a pool of PLA near the metal break. The grub screw does not do a good enough job holding things tightly in place. There should be more than one silicone cap included because it seems to tear around the edges. One of bolts that secure the thermal probe in place have stripped on me already and there is not an included replacement on that either. Also, the Thermister does not have anything that holds it securely in place. This is really not a major upgrade from the e3v2 hotend and I regret purchasing it. (Less than a month)

-

thomas tallagnon

> 3 dayNothing

-

Boring Boss

01-06-2025Ive purchased three of these for my Creality printers, I bought the latest one August 9th 2019. Three major flaws in the latest one. 1. The Bowden tube can slide out randomly, within the first minute or two of printing. 2. The set screw does not keep the heating block from rotating. 3. Filament is extruded through the thermistor hole. A minor fourth complaint would be the heat break ID was really tight on all the filament I tried to run through it cold. Ive seen this with other heat breaks and have a drill bit that cleans up whatever is left over from machining. So this wasnt as bad a problem as the three above. I love my other Micro Swiss all-metals but am leery of buying any more if their manufacturing quality is lower than the first few I purchased.

-

shane a kinton

> 3 dayI have been running ABS thru this constantly for about the last 6 weeks. Does a great job. Printer is Creality CR-10S Pro v2.

-

techadept

> 3 dayLove this hotend. Follow the directions for changing filament or you will have issue.

-

Aaron Winchester

> 3 dayIt doesnt come with extra nozles. It wod be nice to have it come with a .2 and 1mm nozzle with maybe 2 other .4 nozzles.