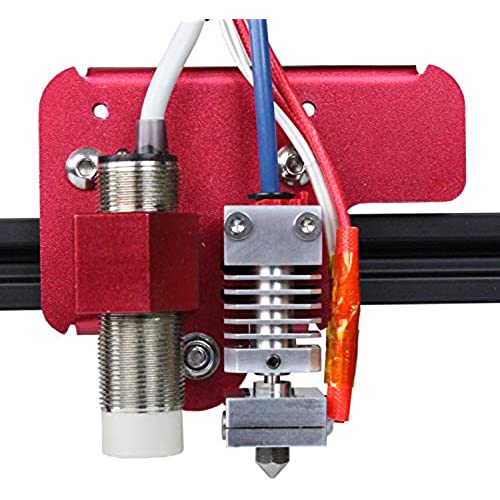

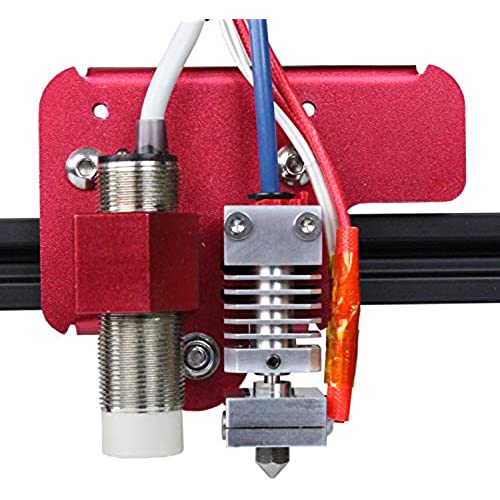

Micro-Swiss All Metal Hotend Kit for Creality CR-10s PRO/CR-10 Max/Ender 3 V2 Neo

-

Roberto

> 24 hourI was worried that this unit might not fit my CR10S Pro because I have installed a 3D printed Fang style print cooling fan/duct assembly. No worries, this hotend was a perfect fit and only took a few minutes to install. I reduced my retraction settings from 8 to 4 and the retraction speed from 80mm/s to 50mm/sec. The first few prints with the new Micro Swiss hotend are as good or better than any print to come off this machine. Im quite happy with this product. I just wish it were a few dollars less expensive.

-

Austin bob

> 24 hourNice extruder needs so modifications to design to keep the grub screw from stripping. Need to tap the right or left side for a longer grub screw the same size to give more threads to bite on too, if you remove the grub screw a few time like 10 over the years the threads get wreckt. Also a longer grub screw to fully take advantage of the very small amount of threads would have also helped the problem, poor engineering. Excellent quality overall. Wouldnt suggest the price point till they redesign the extruder. That is the only problem Ive ever had with it.

-

Johnny M.

> 24 hourThis started out strong. Good prints. But now, it has died. Well, inside the part that screws to the heater block with a tiny allen screw eventually died. And no matter what I do, it just doesnt print

-

David Rivadeneyra

> 24 hourI am very satisfied with this product... it works perfect on my CR10-S

-

Kurtis W Golding

> 24 hourAs I have been slowly gaining more experience with 3D printing, I started hitting some snags when trying to print on glass. After a lot of trial and error, I thought I was getting close. Then, the exiting extruder clogged, impressively. I swapped out the original CR10S Pro V1 print head with this one, and it’s been working perfectly! Just as the directions indicated, it was a simple drop-in replacement. I have not had any clogging, or other issues to speak of. I am now getting very consistent prints with PLA directly on glass! This is super cool because the parts just pop off the bed as it cools. Adding this, in case anyone else is having issues with the CR10S Pro V1 and glass: After some trial and error and seeing my 1st layers being so close to the bed, nothing can be extruded too not close enough to work, I am now sure that the inductive sensor is at fault. If I warm up everything, re-home the printer prior to every print, it works well. (Hoping that the Tiny Machines 3D BL Touch Kit for Creality CR-10S Pro 3D Printers will fix this ... fingers-crossed)

-

Alex Hodge

> 24 hourNot much to like here. The first kit was complete and got to the point of hot tightening the nozzle when the nozzle sheered off in the heat block with the torque driver set to 30 inch pounds as specified. Replacement kit, well I have no idea how the nozzle will fair since its missing the two screws that should be installed in the heater block to hold the heater in place. No way to tighten around the heater. Im going to dig through my tiny screw collection before returning it because I dont want the hassle but Im disappointed. Ive used Micro Swiss on printers in the past and they were great. Its too bad theyve gone so far downhill over the last few years.

-

partime

> 24 hourThe real deal. Works great. One of my favorite upgrades on my CR10 MAX. Has no problem printing at .6 layers

-

Dave

> 24 hourThis is a great drop in replacement. No problems so far with it.

-

Alexis Smith

> 24 hourI have never had so much confidence in my CR10 MAX until I put this on. Biggest difference other than quality is that you can use normal threaded nozzles! Great product. I’m never scared to print even really large things.

-

Richard

> 24 hourAmazing product! Last hotend you’ll ever need