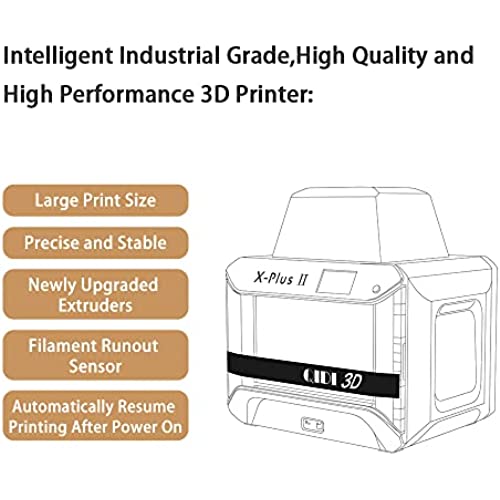

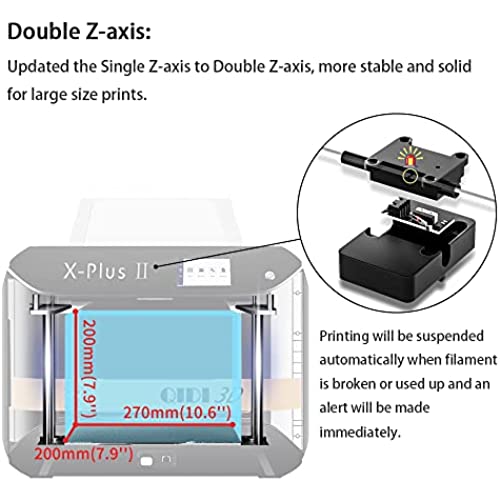

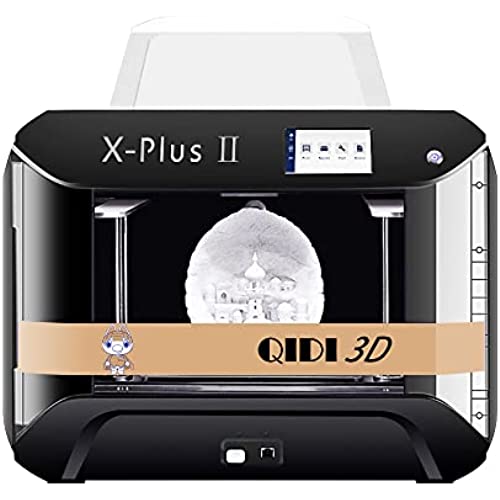

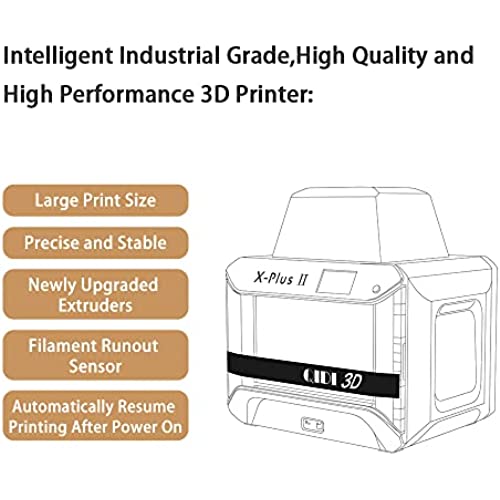

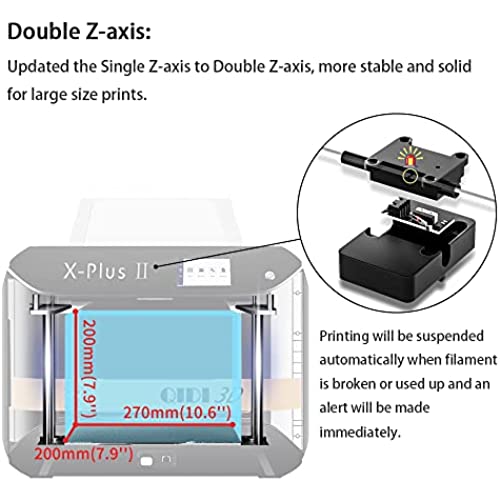

R QIDI TECHNOLOGY X-PlusⅡ 3D Printer, New Upgrade Intelligent Industrial Grade 3D Printers,Large Print Size,Printing with Nylon, Carbon Fiber, PC,High Precision Printing,10.6x7.9x7.9 Inch

-

Old Guy

> 3 dayThis is my second QIDI Tech printer (X-Smart, still going strong) & it’s awesome! I will stick with QIDI printers due to their quality & great customer service.

-

Forrest B.

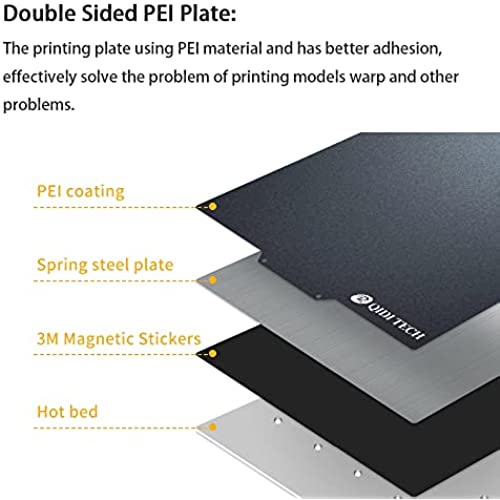

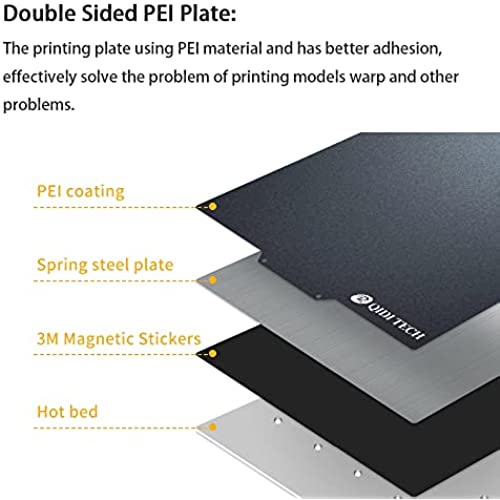

> 3 dayI have used the QIDI printer for a year now and have found it to have superior print quality and is mechanically very robust. I have been printing for 6 years using Flash Forge Pro machines and the QIDI printer has given me a new level of print quality, which my customers really like. The large bed size has opened new markets for my products. With nearly 1,000 print hours on the machine it has proven to be very reliable. I print mostly with ABS and use the BLACK side of the bed plate with a bit of hair spray or glue stick and have had no problems with adhesion or release. The smooth BLACK side gives my products a very smooth surface. I have found that ASA,PLA, CARBON FIBER and PETG work well using this approach. The customer support has been excellent - very responsive and knowledgeable.

-

Prof. Russ Kuhlman

> 3 dayThis was my 4th 3d printer and for the money, it has been a real work horse for me. Of course it prints PLA like many do, but I mainly print with PETg. Using the included high heat hot end makes a real difference with the quality of the PETg prints while the standard one that is installed already prints PLA wonderfully. I love the magnetic bed as prints stick well with just some air spray and then remove nicely with the flexible print surface. I did end up upgrading to the Qidi all metal hot end so I could print higher temp PETg and Nylon without distorting the feeder tube. I will say something about the Qidi support response. I have emailed my Qidi X-Plus support several times with questions and I always get a response within 24 hours. All in all I really enjoy using this printer and for the Price I believe it to be a very good value.

-

P. A. Lenoue

> 3 dayDont be fooled by the reviewers praising this printer, they obviously have never had a filament jam. Doesnt matter how well it prints, youre going to get a jam at some point, and when it happens you might as well throw the entire printer out because you will _NEVER_ be able to disassemble the extruder then reassemble it properly. They designed the extruder assembly in such a way its almost impossible to disassemble in order to get to the problem. To make matters worse, they put in a lot of effort to make sure the screws are tightened as much as physically possible. Ive had to deal with glued screws that were easier to remove. Since they use cheap screws with soft heads this causes the slots to get stripped, thus making it impossible to remove. Everything is so intricately arranged you will never be able to put it back together properly, which is moot because the cheap screws are all stripped and cant be tightened. I can see a dozen ways they could have made the extruding assembly more user friendly, and Im not an engineer, but you have to be one in order to clear out a simple filament jam. The people who designed this never considered the possibility that the end user would have to deal with the problems that always happen with 3D printers, so they never thought to design it to be user friendly. Final recommendation: Dont buy any Qidi printer, once something goes wrong the entire printer is useless. If anyone is starting a class-action suit against Qidi please contact me, I would love to sue them out of existence for their arrogance.

-

J Weaver

> 3 dayIm a relative newbie to 3D Printing. I was looking for a fully featured 3D printer that worked out-of-the-box. I needed a printer both friendly to the beginner and powerful enough to print the most demanding materials. I found it: The QIDI X-PLUS is impressive! The machine came fully assembled. The package included a spool of PLA Pro filament, a regular extruder, an all-metal extruder (swappable), and a small toolkit with some spare parts. It had everything required to get me started! The instructions are simple and clear. I was literally making my very first print within minutes. I went on to successfully print models using PLA, PETG, ABS, ASA, & TPU. And this machine has endured the punishment from my brutal learning process, yet it still works perfectly! NOTES: 1) The heated bed and enclosed chamber help keep the ambient temperature high & prevent warping. 2) The enclosure dampens sound & makes the printing process relatively silent. 3) Vibrations are minimal, thanks to the sturdy, cubic frame. 4) Unlike many printers, the X-PLUS extruder moves on the X and Y-axis, while the bed moves only on the Z-axis. So, you get a superbly detailed print. And you can record quality high-speed videos of the printing without any special equipment! 5) The leveling process, though not automated, is quick and easy. 6) The printing bed is very big! 7) The powerful magnets under the bed hold the build plate perfectly flat. 8) The cabinet is roomy w/ extra space. 9) Filament can be mounted outside or inside the cabinet. 10) The exhaust fan in the back can be controlled & has a carbon filter to help keep odors to a minimum. The QIDI support team is incredibly helpful and responsive. They reply to emails within 24 hours. They consistently work hard to provide clear solutions & guidance. And theyre friendly & courteous. I highly recommend this printer to the beginner or the expert!

-

Mike W.

> 3 dayThis is my first 3D printer. It was easy to set up and use. Prints have been perfect. Highly recommend.

-

Aurelio Rodriguez

> 3 dayEverything works smoothly once everything is leveled right. Love that machine!

-

Fred Cl

> 3 dayThe machine is easy to set up and even easier to use. It took me a while to figure out which 3D drawing program I wanted to use (Fusion 360 it is!). Once I got this done.... Printing with this machine is (I think) as easy as it gets. Last week I received a filament runout sensor. I needed some info from the manufacturer. They were very fast, friendly and very helpful. Ive printed some brackets, buttons and some samples. Most of the products come out pretty nicely. Carbon fiber needs a little more knowledge and experience. The rest is easy. Taking care of the filament is probably one of the most important things to do. It can produce pretty large pieces. If you get this one.... You should be OK!

-

Toofless Tesla

> 3 dayThe quality of the machine is solid and robust (I can testify to this because I fried the circuits the first time I switched on the printer!). This meant I experienced the after-sales service first hand and it was amazing. I can honestly say QiDi’s tech support is fantastic. Within hours the printer was up and running and they provided clear instructions. They also followed up after I had made a few prints, and sent me some spare parts (for free) within a week. I’m thoroughly satisfied with the 3D printer and, what could have been a disaster for me was saved and solved by the excellent tech support. I highly recommend this product and this company.

-

R0k0v

> 3 dayI use this product in personal use for making molds, random useful household objects, minis and any crazy stuff my engineer brain can come up with. I chose this printer over cheaper models because as a working professional doing printing in my free time I didn’t want to have to spend time building an enclosure, upgrading nozzles, or excessively dialing in settings to be able to print PC and ABS with high precision. I wanted something that would be plug and play and provide me with a level of precision that satisfied my engineer’s attention to detail. I have had success printing PC, PC-CF, PETG, ABS, PLA, and TPU. I have had just one issue using this printer and have had about 9 months of use with only one major issue: I shorted and fried my motherboard cleaning the extruder with a wire brush while it was on. This was probably careless of me and was clearly my fault as I wore all the insulating kapton tape off with the brush. Sophia on QIDI’s support team helped me diagnose the issue quickly and provided free replacement parts with easy to follow directions that got my printer back up and running again. Overall the printer has treated me well.